Solar power game-changer: 'Near perfect' absorption of sunlight, from all angles

Researchers at Rensselaer Polytechnic Institute have discovered and demonstrated a new method for overcoming two major hurdles facing solar energy. By developing a new antireflective coating that boosts the amount of sunlight captured by solar panels and allows those panels to absorb the entire solar spectrum from nearly any angle, the research team has moved academia and industry closer to realizing high-efficiency, cost-effective solar power.

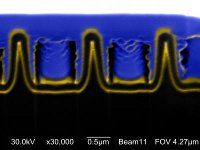

Rensselaer/Shawn Lin

"To get maximum efficiency when converting solar power into electricity, you want a solar panel that can absorb nearly every single photon of light, regardless of the sun's position in the sky," said Shawn-Yu Lin, professor of physics at Rensselaer and a member of the university's Future Chips Constellation, who led the research project. "Our new antireflective coating makes this possible."

Results of the year-long project are explained in the paper "Realization of a Near Perfect Antireflection Coating for Silicon Solar Energy," published this week by the journal Optics Letters.

An untreated silicon solar cell only absorbs 67.4 percent of sunlight shone upon it — meaning that nearly one-third of that sunlight is reflected away and thus unharvestable. From an economic and efficiency perspective, this unharvested light is wasted potential and a major barrier hampering the proliferation and widespread adoption of solar power.

After a silicon surface was treated with Lin's new nanoengineered reflective coating, however, the material absorbed 96.21 percent of sunlight shone upon it — meaning that only 3.79 percent of the sunlight was reflected and unharvested. This huge gain in absorption was consistent across the entire spectrum of sunlight, from UV to visible light and infrared, and moves solar power a significant step forward toward economic viability.

Lin's discovery could antiquate automated solar arrays, as his antireflective coating absorbs sunlight evenly and equally from all angles. This means that a stationary solar panel treated with the coating would absorb 96.21 percent of sunlight no matter the position of the sun in the sky. So along with significantly better absorption of sunlight, Lin's discovery could also enable a new generation of stationary, more cost-efficient solar arrays.

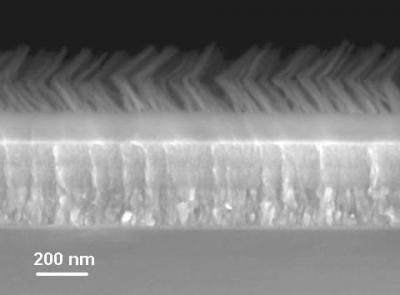

Typical antireflective coatings are engineered to transmit light of one particular wavelength. Lin's new coating stacks seven of these layers, one on top of the other, in such a way that each layer enhances the antireflective properties of the layer below it. These additional layers also help to "bend" the flow of sunlight to an angle that augments the coating's antireflective properties. This means that each layer not only transmits sunlight, it also helps to capture any light that may have otherwise been reflected off of the layers below it.

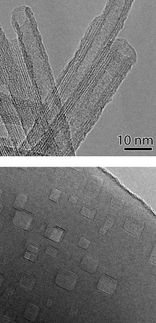

The seven layers, each with a height of 50 nanometers to 100 nanometers, are made up of silicon dioxide and titanium dioxide nanorods positioned at an oblique angle — each layer looks and functions similar to a dense forest where sunlight is "captured" between the trees. The nanorods were attached to a silicon substrate via chemical vapor disposition, and Lin said the new coating can be affixed to nearly any photovoltaic materials for use in solar cells, including III-V multi-junction and cadmium telluride.

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.