Sniffing out a better chemical sensor

Researchers at the NIST have created a new approach for “electronic noses”

Marrying a sensitive detector technology capable of distinguishing hundreds of different chemical compounds with a pattern-recognition module that mimics the way animals recognize odors, researchers at the National Institute of Standards and Technology (NIST) have created a new approach for “electronic noses.” Described in a recent paper,* their electronic nose is more adept than conventional methodologies at recognizing molecular features even for chemicals it has not been trained to detect and is also robust enough to deal with changes in sensor response that come with wear and tear. The detector could be a potent tool for applications such as sniffing out nerve agents, environmental contaminants, and trace indicators of disease, in addition to monitoring industrial processes and aiding in space exploration.

NIST

In animals, odorant molecules in the air enter the nostrils and bind with sensory neurons in the nose that convert the chemical interactions into an electrical signal that the brain interprets as a smell. In humans, there are about 350 types of sensory neurons and many copies of each type; dogs and mice have several hundreds more types of sensory neurons than that. Odor recognition proceeds in a step-by-step fashion where the chemical identity is gradually resolved: initial coarse information (e.g. ice-cream is fruit-flavored vs. chocolate) is refined over time to allow finer discrimination (strawberry vs. raspberry). This biological approach inspired the researchers to develop a parallel “divide and conquer” method for use with the electronic nose.

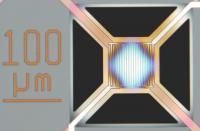

The technology is based on interactions between chemical species and semiconducting sensing materials placed on top of MEMS microheater platforms developed at NIST. (See “NIST ‘Microhotplate’ May Help Search for Extraterrestrial Life,” NIST Tech Beat, Oct., 2001.) The electronic nose employed in the current work is comprised of eight types of sensors in the form of oxide films deposited on the surfaces of 16 microheaters, with two copies of each material. Precise control of the individual heating elements allows the scientists to treat each of them as a collection of “virtual” sensors at 350 temperature increments between 150 to 500 °C, increasing the number of sensors to about 5,600. The combination of the sensing films and the ability to vary the temperature gives the device the analytical equivalent of a snoot full of sensory neurons.

Much like people detect and remember many different smells and use that knowledge to generalize about smells they haven’t encountered before, the electronic nose also needs to be trained to recognize the chemical signatures of different smells before it can deal with unknowns. The great advantage of this system, according to NIST researchers Barani Raman and Steve Semancik, is that you don’t need to expose the array to every chemical it could come in contact with in order to recognize and/or classify them. Breaking the identification process down into simple, small, discrete steps using the most information rich data also avoids ‘noisy’ portions of the sensor response, thereby incorporating robustness against the effects of sensor drift or aging.

The researchers say that they are continuing to work on applications involving rapid identification of chemicals in unknown backgrounds or in a complex cocktail.

Original publication: B. Raman, J. L. Hertz, K. D. Benkstein and S. Semancik. Bioinspired methodology for artificial olfaction. Analytical Chemistry. Published online Oct. 2008

Other news from the department research and development

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.