Delft University of Technology patent for manufacturing radio isotopes

Advertisement

Thanks to a newly-developed technology at the Delft University of Technology in the Netherlands, global shortages of radio isotopes for cancer diagnosis could be a thing of the past. This is the message from Prof. Bert Wolterbeek of Delft University of Technology's Reactor Institute Delft (RID) in an article in university journal Delta.

It has made global headlines recently: hospitals are facing a shortage of radio isotopes which means that patients will have to wait longer for cancer diagnosis. Only a handful of reactors around the world manufacture the isotope, technetium-99m, which is used to treat about forty million patients annually. Three of these reactors are currently unable to supply any due to maintenance work, including Europe's most important: the Dutch reactor in Petten.

Additional isotope manufacturers would reduce the risk of shortages considerably. The current process requires enriched uranium. And that is the kind of material for which manufacturers need a special permit due to nuclear non-proliferation treaties. Prof. Bert Wolterbeek of the RID is working on a radical solution to this problem. He is developing a method for producing the sought-after isotope without uranium. If these experiments prove to be applicable in an industrial environment, many more factories could manufacture the material.

"Technetium-99m, the material in question, is currently made by highly enriched uranium fission," Wolterbeek explains. "One of the products created is radioactive molybdenum-99, the raw material for technetium-99m. Manufacturers supply this molybdenum to hospitals secured in rods. A hospital can 'harvest' the technetium-99m isotope from a rod for a week as the molybdeen-99 slowly decays into technetium-99m."

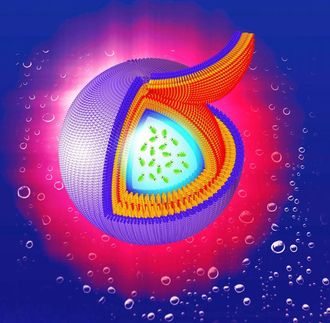

Yet molybdenum-99 can also be manufactured from molybdenum-98, a stable isotope made of natural molybdenum. Wolterbeek has patented a technique in which he bombards this raw material with neutrons in order to make molybdenum-99. The molybdenum atoms are not just 'activated' by the neutron bombardment, but are also separated from the surrounding atoms by the energy transfer. The resultant molybdenum-99 can then be dissolved in water. This means that the isotope can be produced in highly concentrated form. And this aspect is crucial. Wolterbeek: "The activity concentration of the radioactive material needs to be high, otherwise patients will be given too high a chemical dose to form a clear radiation image."

Most read news

Topics

Organizations

Other news from the department research and development

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.