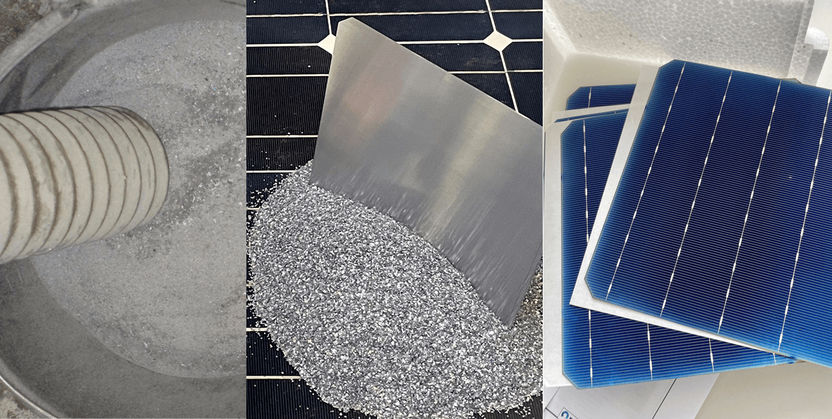

Dow Corning Demonstrates Manufacturing Process and Materials that Significantly Increases Solar Panel Production Rates

Developmental encapsulant series and process being piloted at new Dow Corning Solar Solutions Application Center

Dow Corning Corp. has demonstrated a manufacturing process featuring new developmental silicone materials that significantly increases the production rate of solar panels, effectively lowering the cost per watt of solar power.

“This technology represents a real step-change in the industry, and will help make solar power a viable and sustainable energy option globally,” said Gaetan Borgers, global industry director, Dow Corning Solar Market Business Unit.

The manufacturing process works in conjunction with developmental Dow Corning® PV-6100 Encapsulant series, which provides a clear laminate to protect each solar cell in a panel and can replace commonly used ethyl vinyl acetate resin. The silicone-based material provides higher watt efficiency, longer module life, and optimum UV resistance. Equipment for the new process requires less capital and less factory space. The process and encapsulant series are being piloted by select solar partners in the new Dow Corning Solar Application Center in Freeland, Michigan and are expected to be commercially available in mid-2009.

“We’ve made significant progress in the past year in being able to take technology from the lab to production scale,” said Eric Peeters, global executive director, Dow Corning Solar Market Business Unit. “This solution is an example of our commitment to finding the best technical approaches for helping our customers meet their solar solution development challenges.”

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Carl Zeiss Foundation donates EUR 850,000 to the Advanced Lab for Electrochemistry and Electroorganic Synthesis - Research structure concept of ELYSION enhances the relevance in the fields of electroconversion and electroactive materials

A. Schulman Names Todd Nichols Sales Manager for its Engineered Plastics, North America Business Unit

SABIC Europe to increase prices for PP Automotive grades

Palladium use in diesel emission control systems for cars now a reality

PPG Completes Acquisition of Dyrup

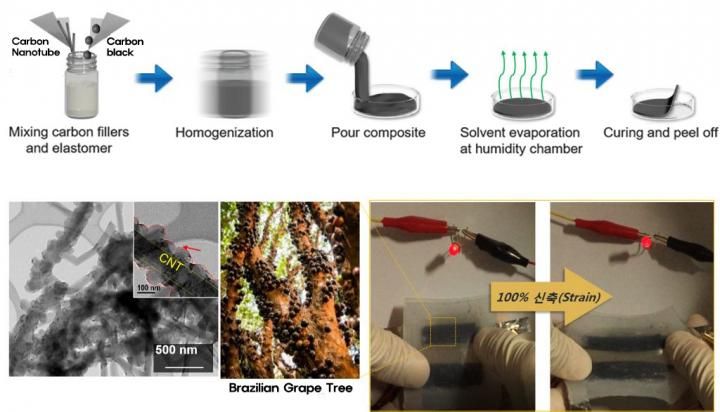

Highly stretchable aqueous batteries developed

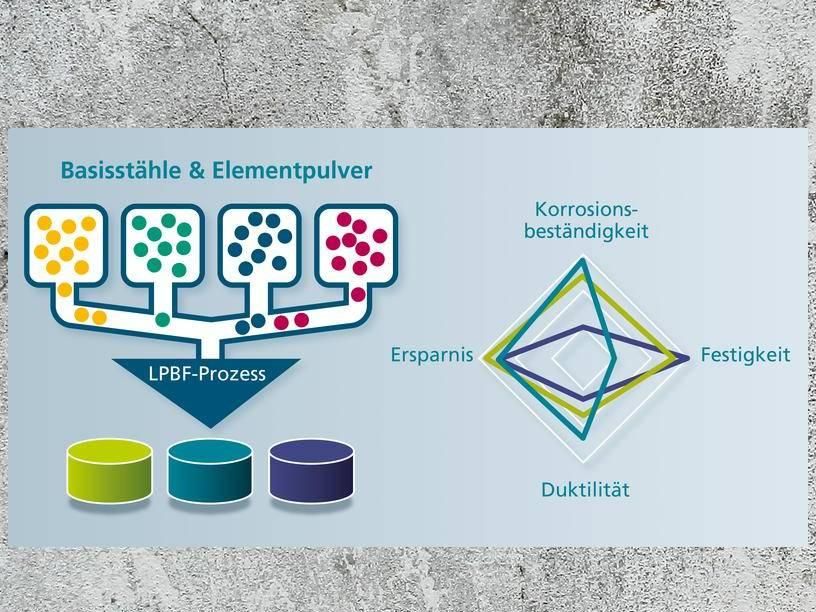

Materials by recipe - Powder kit for more flexibility and material diversity in 3D printing

SABIC Innovative Plastics Wins 2007 National Energy Globe Award for Brine Recovery Project at Bergen op Zoom Facility

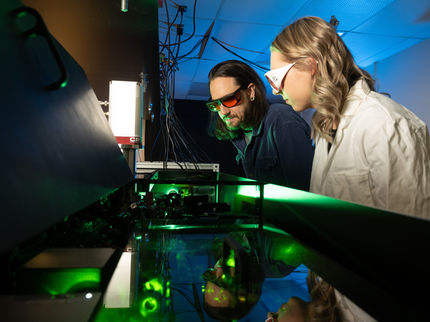

World's tiniest mirror