Engineers whip up the first long-lived nanoscale bubbles

Discovery could significantly extend the lifetimes of common gas-liquid products

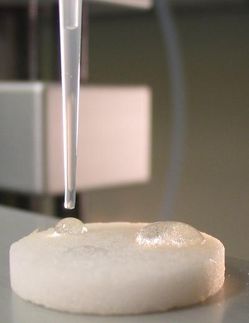

With the aid of kitchen mixers, engineers at Harvard's School of Engineering and Applied Sciences (SEAS) have whipped up, for the first time, permanent nanoscale bubbles - bubbles that endure for more than a year - from batches of foam made from a mixture of glucose syrup, sucrose stearate, and water. Their study appears in the journal Science.

The research, led by Howard A. Stone, had its origins in a conference talk on foams delivered by Dr. Rodney Bee, a retired Unilever physical chemist, in 2005. Bee, who had been researching ice cream for the food, beverage, and personal-care product company, was interested in finding ways to extend the life of foams and other gas-infused mixtures like ice cream. He had produced an unusual bubble formation in the course of his research, and he included a photograph of it in the presentation.

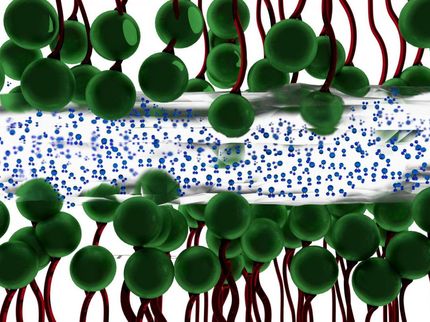

Stone, Vicky Joseph Professor of Engineering and Applied Mathematics and associate dean for applied physical sciences and engineering, was in the audience when Bee projected an image of a micrometer-size bubble with a distinctive polygonal geometry. The bubble surface appeared to be faceted with regular pentagonal, hexagonal, and heptagonal domains that intersected to form a soccer ball-like structure. None of the faces spanned more than 50 nanometers.

"Small bubbles on that scale never last because of surface tension - they instantly disappear. What Rodney showed on that screen was extraordinary," said Stone. "It was impossible; we all thought it was impossible."

Smaller bubbles have a greater surface tension and a higher gas pressure than larger ones. As a result, larger bubbles usually grow at the expense of smaller ones, which have very short lifetimes.

"I asked him how he created his foams, and he said he used an ordinary kitchen mixer. The next day I went out and bought a kitchen mixer for the lab," explained Stone.

The experimental study, conducted by SEAS graduate student Emilie Dressaire in collaboration with Unilever colleagues, revealed that when the bubbles were covered with the chosen surfactant mixture, the surfactant molecules crystallized to form nearly impermeable shells over the bubble surfaces.

The resulting shells possessed an elasticity that allowed them to buckle over time into a remarkably regular and stable pattern. Measurements of the microbubbles' stability extended over more than a year, and the structural integrity of the bubbles held for the entire period.

The authors note that future applications of these microbubbles could significantly extend the lifetimes of common gas-liquid products that experience rapid disintegration, such as aerated personal-care products and contrast agents for ultrasound imaging.

Organizations

Other news from the department science

These products might interest you

2mag Magnetic Stirrers Catalogue 2024 by 2mag

Wear-free magnetic stirrers for laboratory and cell culture

Request the 2mag catalogue 2024 with innovative stirring solutions now

THINKY ARE-250 by C3 Prozess- und Analysentechnik

Perfect mixing and effective degassing in record time - Discover the revolutionary solution for your mixing and degassing needs

THINKY ARE-500 by C3 Prozess- und Analysentechnik

Efficient mixing and degassing in minutes - The revolutionary mixer and disperser without stirrer

Impulsmischer by Hybrid Chemie

Pneumatic mixer for homogenizing solutions, suspensions and emulsions

Gentle, efficient mixing, regardless of the fill level, even for high viscosities

Mini Vortex Mixers by Ohaus

Your vortex mixer for perfect mixing in any application

Your durable laboratory assistant for everyday mixing and vortexing

OHAUS Laboratory equipment by Ohaus

Do More with OHAUS Laboratory Equipment

Do Not Limit Yourself to Just Measurement! Discover Ingenious Portfolio

YSTRAL Conti-TDS by ystral

YSTRAL Conti-TDS: The No. 1 in Powder Wetting

Induct, wet and disperse powder

MultiDrive by IKA Werke

The Universal Crusher: Weigh and Crush Using the Same Mixing Cup!

Mix, grind, disperse – no matter whether your samples are hard, soft or fibrous

Innovative Magnetic Stirrers by 2mag

Magnetic stirrer of the future - for laboratories and pilot plants

Individually configurable, 100 % wear-free, 3-year guarantee

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.