Leeds research brings terahertz closer to everyday use

Advertisement

A collaboration between the Universities of Leeds and Harvard has turned the heat up on terahertz technology, bringing a handheld terahertz device a step closer to reality. The Leeds team, led by Professors Edmund Linfield and Giles Davies from the Faculty of Engineering, has recorded the highest operating temperature for a terahertz quantum cascade laser - a technology that scientists believe may unlock the potential of the terahertz frequency range.

Professor Linfield explains: "The potential uses for terahertz technology are huge, but at the moment they are limited to niche applications in, for example, the pharmaceutical industry and astronomy, as the current systems on the market are expensive and physically quite large. The availability of cheap, compact systems would open up a wide range of opportunities in fields including industrial process monitoring, atmospheric science, and medicine."

Key to exploiting terahertz technology is the production of handheld devices, and one specific type of laser - the quantum cascade laser - will allow the creation of a terahertz device that is small and portable. The problem is, at the moment this type of laser will only function at temperatures of minus 100°C.

So the challenge is to create a terahertz quantum cascade laser which will work at room temperature. While the groups from Leeds and Harvard are still a way off from this, they have succeeded in increasing the laser's operating temperature by nearly ten degrees, and believe they have the means to improve it yet further.

"We hope to obtain further advances by optimising the methods we used to create the device," explains Professor Linfield. "We have some radically new design ideas, and also believe that we can make significant improvements in the way we fabricate the lasers."

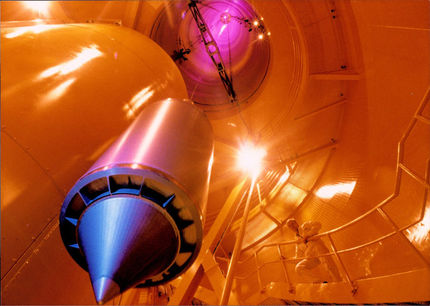

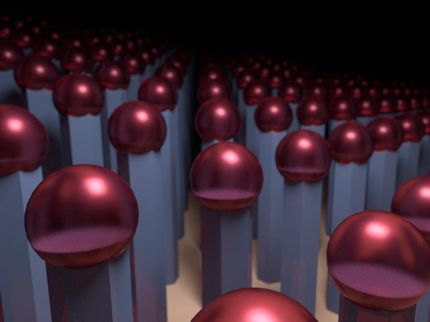

Terahertz quantum cascade lasers are created by building layers of compounds of aluminium, gallium and arsenic one atomic monolayer at a time, through a process known as molecular beam epitaxy. Leeds' Faculty of Engineering is one of a small number of laboratories in the world actively 'growing' terahertz quantum cascade lasers at this time, using a molecular beam epitaxy system purchased through the Science Research Infrastructure Fund (SRIF).

In molecular beam epitaxy, the chemicals evaporate from heated cells, and land on a heated, rotating, substrate. Minute changes in temperature, combined with a set of shutters that block the chemical beams, enable the team to adjust the amount of each chemical which is deposited on the substrate, gradually building up the layers they need. To ensure the device works perfectly, there must be no pollutants, so the process is carried out under ultra-high vacuum conditions, approaching the vacuum levels found in outer space.

The equipment and expert use of it by Professor Linfield and his team enabled them to create a device of superior quality. They now believe that they can bring handheld terahertz technology a step closer still.