Nanotubes Go With the Flow

Nanochannels impose order by capillary action

Advertisement

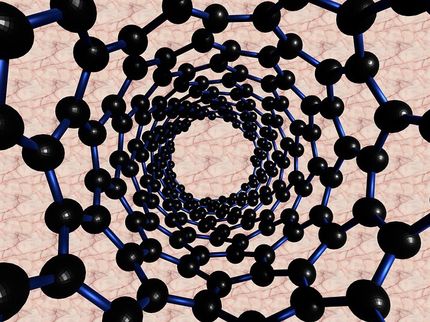

Carbon nanotubes are attractive candidates for use as the active elements in the next generation of electronic devices. However, it has proven incredibly difficult to align nanotubes within device architectures. Most of the approaches for lining up carbon nanotubes reported until now are only applicable to discrete devices and are not readily scalable to the levels required for the mass production of nanotube-based chips. Now, this seemingly intractable problem has been overcome by a collaborative team of researchers from Seoul National University and Sungkyunkwan in South Korea. Kahp Suh and his colleagues have developed a technique for aligning nanotubes over large areas based on the flow of a nanotube-containing solution through nanochannels. This technique is especially attractive because of its simplicity; no external stimuli such as the application of an electric field or syringe pumping are required to align the nanotubes.

This novel approach for aligning carbon nanotubes is based on the simple flow of a nanotube solution through a nanochannel fabricated from a charged polymeric mold. The nanotubes are ordered within the channels by the influence of the capillary force existing within the confines of the channel. When the channels are of the correct geometry, aqueous solutions containing nanotubes enter from both ends, and upon evaporation leave behind dense and highly oriented arrays of nanotubes. Suh cautions that the mechanical properties and surface chemistry of the polymeric mold used for making the nanochannels are of paramount importance. "The stiffness of the polymer has to be just right", says Suh, "it has to be rigid enough to keep the nanochannels from collapsing but flexible enough to bond well with the substrate over a large area". Good adhesion is required between the nanochannel and the substrate to prevent the polymer nanochannels from coming unstuck upon the introduction of the aqueous nanotube solution. The researchers have found that polyethylene glycol diacrylate has the right combination of properties for use as the polymer mold. It is negatively charged and facilitates conformal contact with the substrate. Moreover, it is hydrophilic and thus the nanotube solution is able to enter and flow through the channels without need for additional pumping.

Suh further added that this approach represents a promising advance for the integration of nanotubes in microscale devices. The use of fluidics to bring typically unruly bundles of nanotubes into line may help to solve prevailing bottlenecks for scaling up the production of nanotube devices.

Original publication: Kahp Y. Suh et al.; "Capillarity-Driven Fluidic Alignment of Single-Walled Carbon Nanotubes in Reversibly Bonded Nanochannels"; Small 2008, 4, No. 1, 92-95.