Two million tons of propionic acid made by BASF

Capacity expansion at Ludwigshafen and Nanjing

News Release past 55 years. The versatile acid is a classic product in the company's globally unparalleled portfolio of about 600 intermediates. In view of the high demand for the multifaceted chemical, BASF announced in August that it is planning to expand its capacities in Ludwigshafen and Nanjing.

In 1941, Professor Walter Reppe, a BASF chemist always keen on experimenting, managed to synthesize propionic acid from ethylene. Ten years later, BASF built a pilot plant, and the production started just another year later. Designed for 1,200 tons per annum, the plant was soon unable to meet the constantly rising demand. So in 1960 a new large-scale plant was built that continues to make propionic acid today. "The synthesis is still based on the principle developed by Reppe, but over the years we have optimized and expanded the plant so that production is now much more efficient", explains Dr. Horst Neuhauser, who is responsible for the production of propionic acid.

The importance of propionic acid is quite different now from what it used to be in Reppe's time. In those days, nearly 70 percent of the total volume was used to make vinyl propionate. Processed into polymer dispersions, the acid was ultimately used as decorative exterior paint for buildings. Today, the acid's main field of application is in preserving feed grain. BASF markets propionic-acid-based preservatives under the trade names Lupro-Grain® and Luprosil®.

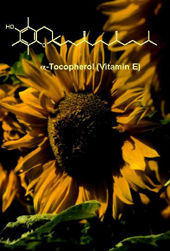

The organic acid is also widely used in the production of vitamin E and in the fields of pharmaceuticals, crop protection agents, solvents, food preservatives and plastics.

With demand continuing to rise, BASF is planning to increase capacity for propionic acid in Ludwigshafen by about 30,000 metric tons per year by mid-2009. As the company announced in August 2007, it also plans to add another 9,000 metric tons per year to its capacity in Nanjing, China. By mid-2009, when the expansion of these two production facilities is completed, BASF will therefore have the capacity to produce 149,000 tons of propionic acid each year.

Most read news

Topics

Organizations

Other news from the department manufacturing

These products might interest you

ERBAdry by CARLO ERBA Reagents

Anhydrous solvents from CARLO ERBA Reagents in a clever redesign

ERBAdry series impresses with the latest generation of septa and sealing caps

Thermo Scientific™ Dionex™ ASE™ 150 or 350 Accelerated Solvent Extractor systems by Thermo Fisher Scientific

Accelerated Solvent Extraction (ASE) – Maximize results and reduce errors in food analysis!

More extractions in less time using less solvent

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.