BOC`s new helium recovery technology boon to fiber optics industry

Advertisement

Murray Hill, New Jersey, USA, January 8, 2002 - BOC (NYSE:BOX), the world's largest helium marketer, has patented a new helium recovery system that offers optical fiber manufacturers significantly reduced operating costs and increased security of supply.

"Helium recovery and recycling is a significant new tool for optical fiber manufacturers, especially during this period of rising helium prices and uncertain supply, " says Art Shirley, director of commercialization and technology, fiber optic solutions, BOC. "It will give them on-site control over their source of helium supply and help them reduce operating costs."

The demand for helium in fiber optics is substantial and growing rapidly. Fiber optics already consumes about 15 percent of the helium on the market, and demand is expected to increase significantly in future years. However, the supply of helium, which is extracted as a by-product from natural gas, is nearly sold out and no significant new supply sources are expected until at least 2004. The result is steeply increasing prices for helium and correspondingly higher operating costs for optical fiber manufacturers.

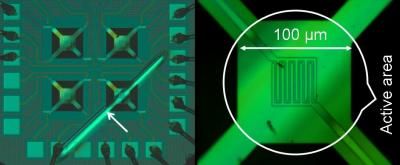

To produce fibers, a silica preform is lowered into a furnace situated at the top of a draw tower. As the silica softens and melts, a thin strand of fiber is drawn from the preform, and rapidly cooled in a flow of helium before it is coated with a resin for extra strength.

BOC's new technology recovers helium from the cooling tower at 99 percent purity and recycles it to the plant for re-use. "Its ease of integration with the fiber draw process, ease of use, high recycling rate and reliability are great advantages for optical fiber manufacturers," says Igor Shedletsky, BOC's commercial manager for helium recovery. "The system collects nearly all of the helium used in the cooling tower, enabling us to recover as much as 85 percent for recycle. In addition, BOC can remotely monitor its operation, adding to its reliability and ensuring that the highest possible recovery is achieved."

The helium recovery technology was first demonstrated in Australia in 1998 and has subsequently been evaluated at fiber optic production sites in China, Taiwan and the United States. "In each case the system maintained constant helium purity and recovery without any detrimental effect on the cooling process or fiber quality," Shedletsky adds.