Nanoscale Cubes and Spheres

Uniform porous silicon oxide nano-objects formed by controlled disassembly of a lattice structure

Porous nano-objects with defined sizes and structures are particularly interesting, for example, as capsules for enzymes, a means of transport for pharmaceutical agents, or building blocks for larger nanostructures. The production of such tiny, three-dimensional objects in a targeted and controlled manner - and as simply and efficiently as possible - remains a challenge for scientists. At the University of Minnesota, a team led by Andreas Stein has now developed an interesting new process for the production of nanoscopic cubes and spheres of silicon dioxide. Instead of building their particles from smaller units, they used the controlled disassembly of larger, lattice-like structures.

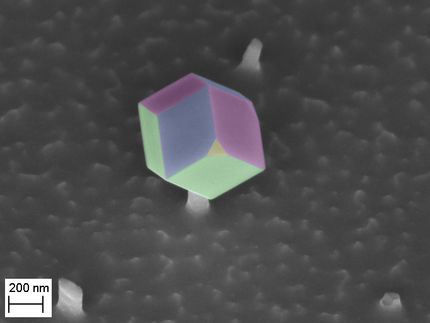

Most conventional methods for the production of porous silicon dioxide nanoparticles suffer from the fact that the growing particles tend to aggregate, making it difficult to achieve a uniform size. The shape of the particles can hardly be influenced at all. Stein and his team chose a backward approach, first building up a lattice structure of silicon dioxide and then disassembling it to get the shape they wanted. The "moulds" used for the lattice were tiny spheres of a plastic called polymethylmethacrylate (PMMA), which assemble themselves through "closest packing of spheres" into a colloidal crystal. Between the spheres in this structure, there are little, nearly tetrahedral and nearly octahedral spaces. The researchers filled these cavities with a solution containing an organosilicon compound, oxalic acid, and a surfactant. This mixture hardens into a solid gel. The plastic spheres and surfactant are then burned off by heating. The surfactant leaves behind tiny pores, and the gelled organosilicon compound slowly converts to a solid silicon oxide. What remains initially is a silicate lattice that is the negative of the packed spheres: tiny tetrahedra and octahedra attached to each other by delicate bridges. As the conversion to silicon dioxide continues, the structure shrinks until it breaks at the weakest points-the bridges. The fragments formed by this process are shaped like octahedra or smaller tetrahedra. These continue to contract until the octahedra become nearly cubic and the tetrahedra become nearly spherical, making highly uniform structures with worm-like pores.

By varying the colloidal crystals used as the mould, the size and shape of the resulting particles can be controlled. Through vapor deposition or polymer grafting, other compounds can be added to the structure. Subsequent etching away of the silicon oxide allows this new technique to be used as a starting point for nanostructures made of other materials.

Original publication: Andreas Stein et al.; "Shaping Mesoporous Silica Nanoparticles by Disassembly of Hierarchically Porous Structures"; Angewandte Chemie International Edition 2006.

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.