BASF: Innovations in chiral intermediates

Dehydrogenase technology for high-purity products

BASF has developed an innovative process for the production of new chiral intermediates for the pharmaceutical industry that are being made on a commercial scale. These additions expand the company's technology platform for producing optically active styrene oxides and aliphatic alcohols. The new BASF process, based on dehydrogenase biocatalysts, allows for the production of particularly high-purity substances that serve the pharmaceutical industry as important building blocks.

In addition, BASF is expanding its portfolio with two new, multi-faceted chiral amines: (R,R)- and (S,S)-Bis(1-phenylethyl)amine. These process chemicals can be used for the asymmetric synthesis of non natural amino acids and as starting materials for chiral bases (i.e., bases for the asymmetric deprotonation according to Simpkins).

Under the ChiPros® brand, BASF is now supplying a range of chiral amines, alcohols and acids. More than ten years ago the company produced a chiral 1-phenylehtylamine based on a new bio-catalytic process for the first time. Since then, the "ChiPros Building Block Set" has been enlarged continually. The life science industry, its principal customer, uses these products in complex processes to make new medicines and crop protection agents.

Enzymes play a major role in producing these coveted substances. Enzymatic processes make more effective use of starting materials, produce less waste and require less energy. New catalysts must be found constantly for pilot processes converted to industrial-scale production. Our search strategy is based on evolution: Changes in enzymes are made in the laboratory on the basis of mutation and selection. Darwin would find his thinking confirmed, with the difference that we accomplish needed change in days rather than millions of years. Thousands of enzyme variations are developed and screened with the aid of computers. Automatic systems test more than 50,000 substances daily. The most promising candidates are mutated and selected until the optimum enzyme has been achieved.

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

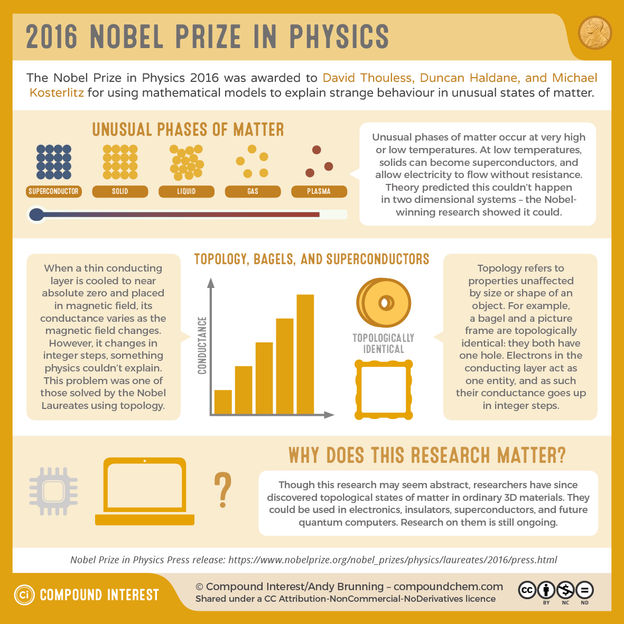

Nobel Prize in Physics 2016

LAUDA declared World Market Leader

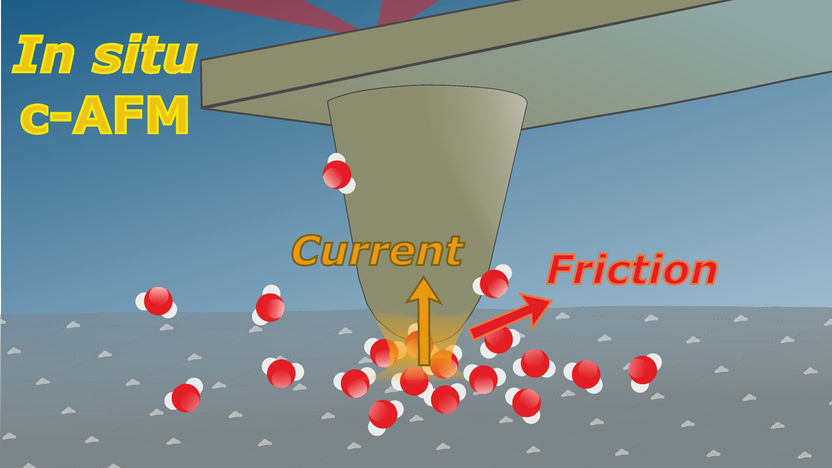

Electrocatalysis under the atomic force microscope - More insights with AFM

Edinburgh Instruments Ltd. - Livingston, United Kingdom

W. Dimer GmbH - Laufenburg, Germany

In chemical reactions, water adds speed without heat

More Electricity from the Sun - Surface modification for more effective textured perovskite/silicon tandem solar cells

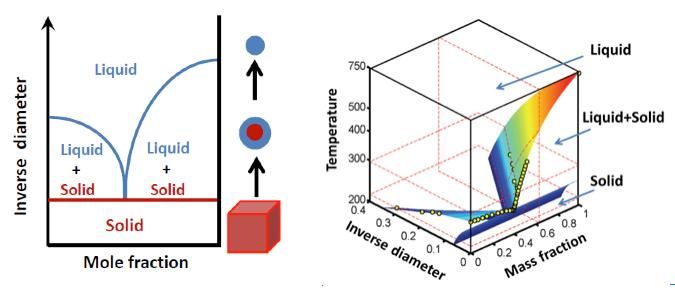

Solid or liquid - the particle size matters - Max Planck researchers elucidate how the phase state of aerosol nanoparticles depends on their size

Climate Change makes Arctic Ozone Loss Worse - The expected recovery of the ozone layer may fail to happen anytime soon, if global warming is not slowed down

Applied Biosystems/MDS Sciex is the Top Supplier in the Mass Spectrometer Market

Fighting microplastics for a cleaner future - Dr. Manish Shetty is working to break down microplastics to create usable fuel