With Terlux from BASF: Greater transparency in medicine

Advertisement

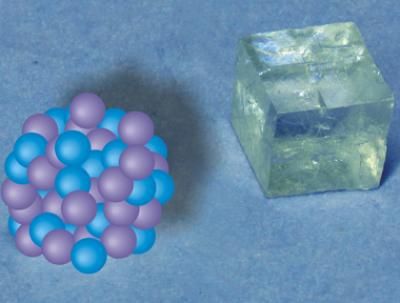

One of the youngest plastics from BASF is Terlux®, a thermoplastic based on methyl methacrylate, acrylonitrile, butadiene and styrene - and consequently abbreviated to MABS. The monomer units are matched to one another in such a way that the resultant material is distinguished not only by toughness and rigidity, but also guarantees very good transparency.

This property combination alone is very attractive to the medical sector. But Terlux can do much more: the material is resistant to greases and oils, water and dilute acids and caustic lyes, and parts made from it can be bonded safely and reliably to, for example, PVC tubes using special solvent adhesives. This makes Terlux the perfect choice for the production of connectors as needed in infusion sets.

Terlux also satisfies another unavoidable prerequisite for materials in medical technology, namely sterilizability. The product is therefore also used as casing material for dialysis filters which are sterilized by gamma rays in doses of 25 to 35 kilogray (2.5 to 3.5 megarad). This does not impair the mechanical properties and functioning of the parts, but gamma rays may cause a certain amount of yellowing - although this effect can be reversed virtually completely if the parts are stored in daylight after irradiation.

Terlux parts can also be sterilized in ethylene oxide or propylene oxide sterilizers. However, Terlux is not suitable for steam sterilization.

Finally, Terlux has also established itself in diagnostics: an example from this area is a cassette for measuring blood clotting tendency. The most important factors here are transparency at certain wavelengths, cracking resistance during ultrasonic welding and resistance to reagents and blood. Terlux meets all these requirements equally.