Smart plastics change shape with light

Picture a flower that opens when facing the sunlight. In work that mimics that sensitivity to light, an MIT engineer and German colleagues have created the first plastics that can be deformed and temporarily fixed in a second, new shape by illumination with light having certain wavelengths. These programmed materials will only switch back to their original shape when exposed to light of specific different wavelengths.

The work, to be reported in Nature, could have potential applications in a variety of fields, including minimally invasive surgery. Imagine, for example, a "string" of plastic that a doctor threads into the body through a tiny incision. When activated by light via a fiber-optic probe, that slender string might change into a corkscrew-shaped stent for keeping blood vessels open. What about staples that open on command, or paper clips that relax as soon as you don't need them anymore? Again, light could do the job. "This is really a new family of materials that can change from one shape to another by having light shined on them," said Institute Professor Robert Langer of MIT. Langer co-authored the paper with Andreas Lendlein, Hongyan Jiang, and Oliver Jünger. Lendlein, a former MIT visiting scientist, is institute director at the GKSS research center in Teltow, Germany. With Jiang and Jünger, he is also affiliated with RWTH Aachen, Germany.

Plastics with "shape-memory" that can change shape in response to a temperature increase are well known. In 2001 Langer and Lendlein were the first to report biodegradable versions of these materials in the Proceedings of the National Academy of Sciences. A year later the researchers introduced thermoplastic, biodegradable shape-memory polymers and demonstrated a nifty application giving a flavor of the innovation potential in the medical field: a smart suture that ties itself into the perfect knot. That work was described in the journal Science; mnemoScience GmbH of Aachen, Germany was developed to commercialize the discovery. "Now instead of heat , we can induce the shape-memory effect in polymers with light," said Lendlein.

Key to the work are "molecular switches," or photosensitive groups that are grafted onto a permanent polymer network. The resulting photosensitive polymer film is then stretched with an external stress, and illuminated with ultraviolet light of a certain wavelength. This prompts the molecular switches to crosslink, or bind one to another. When the light is switched off and the external stress released, the crosslinks remain, maintaining an elongated structure. Exposure to light of another wavelength cleaves the new bonds, allowing the material to spring back to its original shape.

The team notes that in addition to elongated films, a variety of other temporary shapes can be produced. For example, a spiral can be created by exposing only one side of the stretched sample to light. The result is the formation of two layers. So "while the deformation is well-fixed for [the irradiated] layer, the other keeps its elasticity. As a result, one contracts much more than the other when the external stress is released, forming an arch or corkscrew spiral shape," the authors write. The team has also shown that the temporary shapes are "very stable for long times even when heated to 50 degrees C."

"In our Nature paper, the basic principle of photo-induced shape-memory polymers is explained. We are currently developing medical and industrial applications using their photosensitivity," Lendlein said. The work was funded in part by a BioFuture Award from the Bundesministerium für Bildung und Forschung, Germany, and a fellowship from the Alexander von Humboldt Foundation.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Sigma-Aldrich and MorphoSys Enter Into a Collaboration and Licensing Agreement for Recombinant Research Antibodies - AbD Serotec will use proprietary technology to generate antibodies against novel research targets provided by Sigma-Aldrich

Ullmann_condensation

Edmond_Frémy

Borealis to acquire DEXPlastomers

Let there be light: Teaching magnets to do more than just stick around

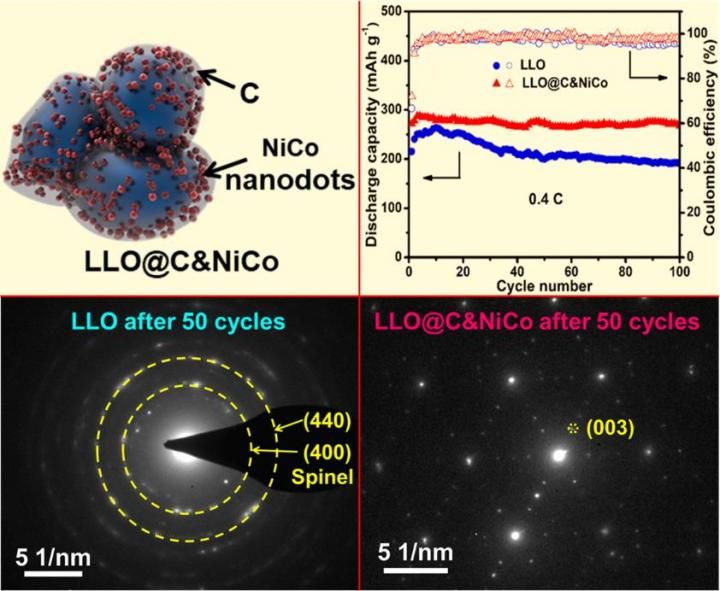

Novel MOF shell-derived surface modification of Li-rich layered oxide cathode