Bayer to build new aniline plant in Antwerp

Bayer MaterialScience plans to build a new aniline production plant in Antwerp, Belgium. It is to have a capacity of 50,000 tons/year and reach completion in early 2006. An innovative process will be used for the first time, which above all cuts investment and manufacturing costs. The construction work is scheduled to begin shortly. "With the new plant, we want to underline not only our market leadership, but most importantly our technology leadership in the field of polyurethane raw materials," says Dr. Tony Van Osselaer, member of Bayer MaterialScience AG Board of Management and responsible for Production & Technology.

The new facility will be in the immediate vicinity of an existing aniline plant in Antwerp, the capacity of which is likewise to be increased by 25,000 tons/year to reach 165,000 tons/year by the end of 2005. The total investment for both projects amounts to some EUR 20 million. Aniline is required for the manufacture of methylene diphenyl diisocyanate (MDI) - a key chemical component in the production of polyurethane foams and elastomers. Rigid insulating foams, for example, are used in refrigerators and freezers, or as thermal insulation in the building industry and district heating pipes. Elastomers are used in the footwear, automotive and electrical industries.

"Worldwide demand for MDI is currently higher than the supply. As a consequence, the demand for aniline is rising at a similar rate. We need the aniline from Antwerp to go ahead with our plans to expand MDI capacities in Europe," says Peter Vanacker, head of the Polyurethanes Business Unit at Bayer MaterialScience. Bayer previously announced its intention to expand capacities at plants in Tarragona (Spain), Baytown (USA) and Brunsbüttel (Germany) by a total of some 140,000 tons/year by 2006. Vanacker: "To underscore our position as market leader, we will then have a global MDI capacity of more than a million tons."

Topics

Organizations

Other news from the department manufacturing

These products might interest you

tritec® Chromatographic refrigerators by tritec für Labortechnik und Umweltsimulation

Energy-efficient chromatography refrigerators for precise temperature control

Safe storage of your HPLC systems at -5 °C to 20 °C with modern touchscreen display

B 35 by FRYKA Kältetechnik

Deep freezer for arctic cold - directly on your lab bench

Your samples - ready to hand thanks to decentralized storage and safely cooled at up to - 85 °C

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Diamond_District,_Manhattan

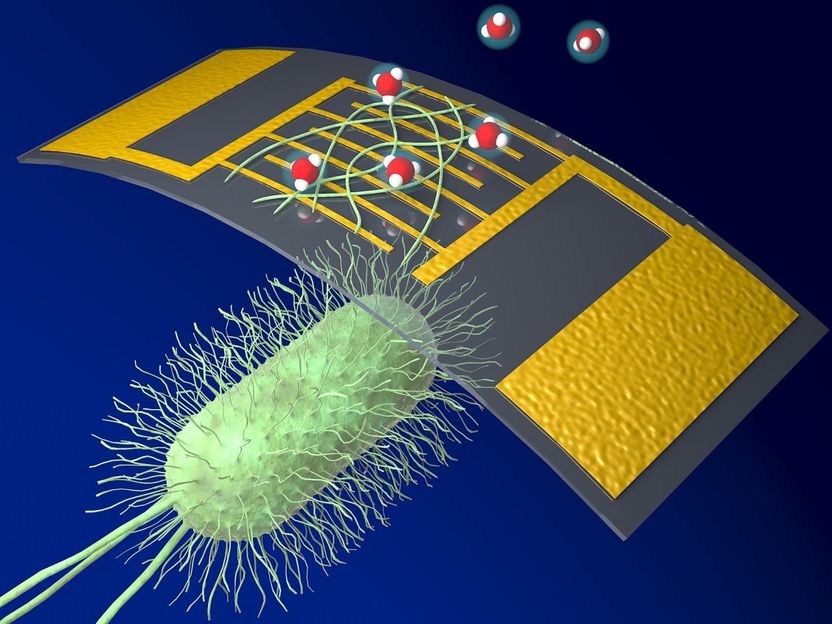

A new, highly sensitive chemical sensor uses protein nanowires - UMass Amherst team introduces high-performing 'green' electronic sensor

ABB wins cable order from Statoil for world’s largest offshore gas platform

Colonial Chemical launches new website for connecting with customers