WACKER POLYSILICON Expands Polysilicon Capacity at Burghausen, Germany

WACKER POLYSILICON continues to expand polysilicon production at its Burghausen site in Germany. Capacity will be ramped up in two stages: from 2006, annual production will rise by 500 metric tons, and by another 1,000 metric tons from 2007. After the expansion program is complete, up to 6,500 metric tons of polysilicon will be produced annually at Burghausen. The investment, totaling approx. EUR 75 million, is mainly due to increased global demand for polycrystalline silicon needed to manufacture solar cells. As a result, some 50 new jobs will be created at the Burghausen site.

The expansion project aims to make available sufficient polysilicon production capacity in the mid term. "The high-growth solar market is causing noticeable bottlenecks worldwide among photovoltaics and electronics producers," says Ewald Schindlbeck, head of the WACKER POLYSILICON Business Division. "Our expansion program has ideally equipped WACKER for the sustained run on solar-grade silicon."

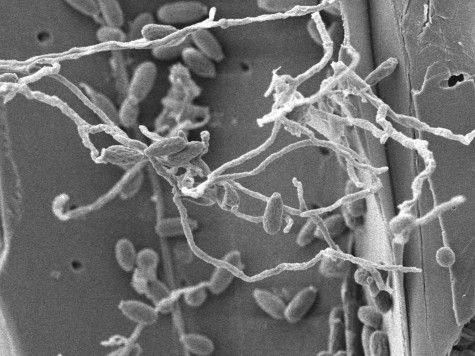

To pursue new avenues of processing photovoltaics-grade silicon crystals, WACKER POLYSILICON is developing an innovative process for producing granular polysilicon. Known as the fluidized-bed process, the new method uses trichlorosilane as a raw material. The advantages of silicon granules are not only their suitability for continuous crystallization processes but also their improved cost-effectiveness in the production of solar-grade silicon. The first two pilot reactors are expected to start operating in October 2004.

Most read news

Topics

Organizations

Other news from the department manufacturing

These products might interest you

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

BUCHI MINICLAVE by C3 Prozess- und Analysentechnik

Flexible small reactor systems - acid resistance, visual control and individual customization options for a wide range of applications!

PhotoSyn™ by Uniqsis

Experience the future of photochemistry

Flow reactor with user-friendly control for higher yields and selectivity

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

BASF starts first MDI production in Chongqing

Clariant continued to grow sales despite a slow start in Plastic & Coatings

'Dominating' fungus could be solution to producing more biofuels and chemicals