Plastics Processing-Emerging Technologies and Trends

While price still remains a critical purchase determinant, selecting the right equipment to realise enhanced productivity and efficiency has become the focal point for plastics processors. This priority is being reflected in the growing number of partnerships between plastics fabricators and machinery suppliers.

"Selecting the right plastics processing equipment is important and it is not always easy to choose correctly given the plethora of equipment suppliers by category, the increasing need for decreased energy consumption on top of equipment functionality and performance and the ever present capital investment quick payback requirement," comments Research Analyst Donald V. Rosato from Technical Insights, a business unit from Frost & Sullivan.

Collaborations between equipment suppliers and plastics fabricators need, therefore, to be flexible regardless of whether the plastics processing equipment is of a primary, auxiliary, software, or services variety. For instance, an off-the-shelf robotic handling system cannot be standardised globally but needs to be adapted to suit regional requirements.

Worldwide, plastic manufacturers are aiming at boosting energy efficiency, upgrading standard equipment capability in terms of labour and material savings, adding cross-product differentiation features and speeding up marketing cycles.

"To develop these high velocity manufacturing systems, emerging cutting-edge plastic processing technologies are the foundation," says Mr. Rosato. "True sustainable lean manufacturing excellence comes, however, with customising company needs to their given manufacturing environment."

The growing need to tailor equipment such as robots to accommodate the plastic fabricators' specific manufacturing environments is gaining particular significance in full manufacturing cells, which are defined by minimal production staff participation and designed for 'lights-out' manufacturing.

As plastics fabricators rationalise operations, primary and auxiliary equipment suppliers are being compelled to change accordingly. For instance, auxiliary equipment supplier Wittmann is locating manufacturing plants in Hungary and China to supplement its Austrian base facility. At the same time, the company has expanded from robot specialisation to become a full-service auxiliary equipment supplier.

Three way partnerships among globally leading plastics manufacturers and their primary/secondary equipment suppliers are becoming a common feature. Many of these partnerships such as that between Nypro, Husky Injection Molding Systems and Hekuma in the area of high-tech state-of-the-art in-mould labelling have proved to be extremely productive and cost effective and have excelled at maintaining the proprietary nature of finished product development.

Whereas plastic fabricator manufacturers have concentrated on accelerated paybacks since they are always looking ahead to new orders, plastics processors have focused on emerging next-generation technologies.

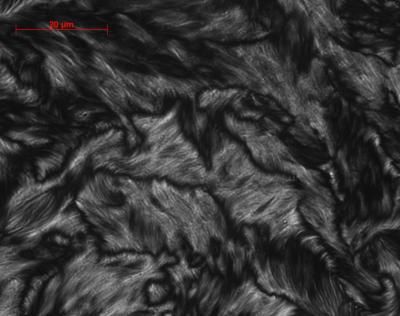

Stellar technical progress has resulted in hybrid hydraulic and electric powered injection moulding machines that now deliver 15-30 per cent faster cycle times and in smart blown film software that has yielded the world's largest and most advanced 9-layer co-extrusion. Embedded production and process monitoring system has been introduced in injection moulding equipment to create a 'boundaryless plant'. An improved technology for hot runner moulding has also emerged, which displays breakthrough gating on angled surfaces.

Most read news

Other news from the department business & finance

These products might interest you

Limsophy by AAC Infotray

Optimise your laboratory processes with Limsophy LIMS

Seamless integration and process optimisation in laboratory data management

LAUDA.LIVE by LAUDA

LAUDA.LIVE - The digital platform for your device management

Comprehensive fleet management options for every LAUDA device - with and without IoT connectivity

ZEISS ZEN core by Carl Zeiss

ZEISS ZEN core - Your Software suite for connected microscopy in laboratory and production

The comprehensive solution for imaging, segmentation, data storage and analysis

ERP-Software GUS-OS Suite by GUS

Holistic ERP solution for companies in the process industry

Integrate all departments for seamless collaboration

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.