WACKER to Build Production Facilities for Redispersible Powders in China

The Munich-based WACKER Group is to commence building a spray drying facility for the production of VINNAPAS® redispersible powders in China this year. WACKER is ensuring that the facility, scheduled to start operations in 2005, will offer world-class technology and capacity. The company is currently checking out several possible locations. The new site's investment costs, including all infrastructural measures, are estimated at EUR 10 million.

The investment is WACKER's response to a rise in world, and especially Chinese, demand for VINNAPAS® redispersible powders that enhance cementitious dry mortars. Experts estimate that the Chinese market for dry mortars is undergoing double-digit annual percentage growth. Building a spray dryer in China will reinforce and further expand WACKER's leading position in this important growth market. WACKER is the world's largest maker of redispersible powders.

The WACKER SPECIALTIES business division has been producing redispersible powders and dispersions for the construction industry for more than 45 years. VINNAPAS® redispersible powders are thermoplastic polymers derived mostly from vinyl acetate and ethylene. They serve as film-forming binders in a large number of applications, including tile adhesives and joint fillers, mineral plasters, sealing slurries, gypsum, repair mortars, self-leveling flooring compounds and powder paints. They enhance important properties in the end product, such as adhesion, cohesion, flexibility and flexural strength. Water retentivity and processing properties also benefit from VINNAPAS®.

China′s growing demand for VINNAPAS® redispersible powders is chiefly due to the need for dependable, lightweight and energy-efficient building materials. More and more Chinese houses are being lined with exterior insulation and finish systems (EIFS). VINNAPAS® is a major component of the specialty mortars used in these systems. The redispersible powder is responsible for ensuring that the individual layers which make up such systems are bonded together permanently. Inside the mortar itself, VINNAPAS® forms a polymeric film that not only improves the adhesion of the mortar, but also makes it more flexible and resistant to impact.

Most read news

Organizations

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

New RoboSeq 2500 DT automated biosystem for molecular biology applications

The Lenzing Group withdraws from US Minority Holding Lenzing Fibers Corporation

Agilent Technologies presents Europhysics Prize for pioneering work with carbon nanotubes

Greiner Bio-One BioScience - established and successful world-wide

LIGA

Caldeira-Leggett_model

Vortex_tube

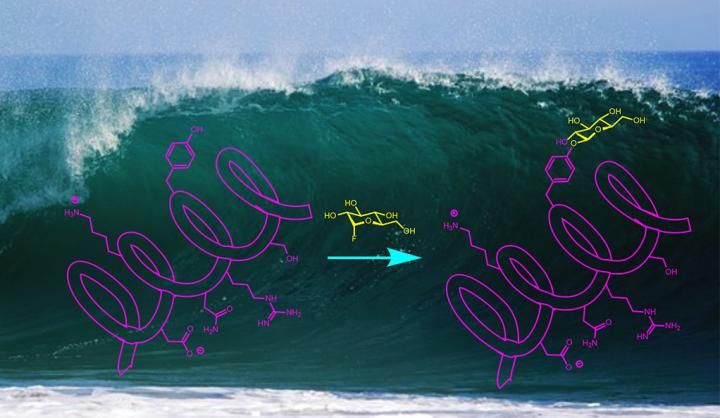

A new formula for creating chemical reactions -- with carbs - New approach to glycosylation that is remarkably simple and works in water at room temperature

Carbon nanotubes twice as strong as once thought