Hydrosulfite - the evergreen among textile auxiliaries turns a hundred

Around 1900 it was apparently still the custom in some dyehouses for the apprentices to have to make an additional contribution of their own to the fermentation vats every morning. Abundant beer consumption the previous evening is supposed to have facilitated this task. This was how the apprentices proved to their superiors that they had a personal attachment to the plant. However, it is understandable that a company that manufactures its products by scientific methods and tries to pass them on to customers with exact directions for use found it necessary to look for another, more appropriate vatting agent.

In 1904, after more than a hundred years of looking for a good vatting product, scientists finally made the break-through: BASF researcher Max Bazlen developed the first stable hydrosulfite. Bazlen heated the unstable hydrosulfite then available to above its dehydration temperature in alkaline alcohol and added salting-out agents. After removing the hot mother liquor, he obtained hydrosulfite as a white, anhydrous product stable to air.

Patent at the last minute

Max Bazlen was doubly lucky. In another BASF laboratory a certain Hermann Wolf had been working on the same material. He too was successful. However, he did not get to the patent office until 30 minutes after his "rival" Bazlen. The Imperial Patent Office finally granted the patent on 4 March. From then on, nothing stood in the way of the triumphant advance of the first Hydrosulfite Conc. BASF. Confident of its effectiveness, BASF even offered a two-year guarantee on the product. Studies showed that a sample of the very first batch had lost only 10 % of its activity after 30 years' storage. And what is more, the same batch was examined again after 50 years, following two world wars. Despite damaged packaging, the reducing power of the hydrosulfite had only fallen 50 %.

Early improvements to the process

To increase the product yield, Max Bazlen's team modified the recipe very early on. The new recipe involved blowing sulfur dioxide through an aqueous slurry of zinc dust, precipitating the zinc with soda, filtering the mixture and salting out the hydrosulfite with alcohol. The product was again anhydrous hydrosulfite. This method became known among specialists as the zinc dust process and was particularly suitable for indigo dyeing.

Simple, clean and also pure

From the beginning, Hydrosulfite Conc. BASF had the reputation of being clean and simple to use in aqueous solution. The product was quick to make and was impressive for the clarity of the vat and the absence of sediment. Moreover, the hydrosulfite left the dye where it was required: on the textile. Other applications for hydrosulfite were rapidly found. It was, for example, ideal for bleaching wool. But further developments in the field of hydrosulfite and related products also played a major role at BASF in the early days. An example was Rongalit® C, a discharge agent for dyeings with direct and acid dyes, but also suitable for direct printing with vat dyes. Another was Decrolin, which became a very successful mixed brand. Decrolin is used mainly to strip reclaimed wool and discharge dyeings, especially those with acid dyes. Hydrosulfite also made an impact outside the textile industry. Specially selected, completely soluble, metal-free batches received the brand name Blankit® and were suitable for bleaching foodstuffs. A hydrosulfite specialty product was developed for bleaching straw, materials and soaps. And from that time on no household could be without the stain remover Burmol®.

"Hydrosulfiters" and stumbling blocks

However, the hydrosulfite route was also beset with one or two stumbling blocks. At the beginning there were problems with production and logistics. The operation of the hydrosulfite plant required a lot of labour for the heavy manual tasks. A report from this period describes the difficulties: "The heavy zinc dust drums had to be moved, the zinc dust had to be filled into the mechanical blowing units, the filter presses operated, the salting-out vats charged with salt, the suction filters emptied, the drying pans filled and emptied, the heavy lids of the drying pans lifted, the drums of finished product transported, and the mixers filled and emptied. The work was always hard and was rendered more difficult by dust and smells." This helps us to picture the old "hydrosulfiter": tough, as demanded by the hard labour, and reliable, as demanded by the sensitivity of the product. Which leads us to the second problem, that of transport. The product was initially sold at cost as an alcohol-based slurry in soldered tins, but in this form did not really take off. Hydrosulfite was at this period still a hazardous commercial product and readily ignited in air. Moreover, its reducing power steadily decreased during transport and storage. Reports at the beginning of the 20th century mention all kinds of costs and inconveniences with regard to freight and customs. But Max Bazlen and his team quickly had these problems under control. The first large-scale production of hydrosulfite in Ludwigshafen started shortly after the product was launched. At the beginning of the thirties it became possible to rationalize the process. Manpower, maintenance costs and energy were saved by making the many individual process steps into a continuous process. Bazlen's successors could say with unmistakable pride: "Nothing is the same as it used to be."

Fluctuating economic circumstances

The launching of synthetic indigos brought with it a high demand for hydrosulfite. On the other hand, the product suffered from the two world wars and the economic crisis, for dyes and dyeing auxiliaries were considered to be the merchandise of peace, prosperity and culture. War and economic depressions often caused their manufacture to drop sharply. True, production recovered rapidly again after each crisis, but after the First World War many states decided to set up their own manufacturing plants for reducing agents and dyes. The German monopoly had been broken. It was small consolation that nearly all dyehouses imitated the Bazlen process. The imitators did not have to reckon with legal measures from BASF, since the patent had already expired in 1922.

Clearing the rubble

After the Second World War, most of the plants at BASF were at a standstill, many having been completely destroyed. The period immediately after 1945 was dominated by clearing work. Obtaining raw materials also constituted a headache for BASF researchers. It was especially difficult at this time to obtain the zinc dust upon which hydrosulfite production depended. In 1947 BASF could only meet 50 % of the demand for hydrosulfite. But this situation also stimulated research into ways of making the product without zinc dust.

In 1951 the plant manager was able to repeat once again: "Nothing is the same as it used to be." The traditional process had been superseded by the new dithionite-amalgam process, which assured the desired independence from zinc dust. In addition, the quality of the hydrosulfite was once more improved.

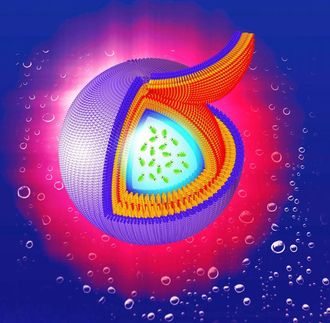

Hydrosulfite today

Since the 1950s, production has increased seven times over. "Hydrosulfite is in the same high demand it has always been. Today BASF is Europe's biggest supplier. The company's two Ludwigshafen plants manufacture hydrosulfite-based products with an annual capacity of 90,000 tonnes. BASF is holding its own as technology leader in hydrosulfite manufacture. Customers are offered a total of 40 individual products, some of them specialties, based on hydrosulfite. 90 % of production is delivered directly to customers from the plant, mostly in metal drums. About three quarters of a million such drums are despatched every year. Modern, largely automated filling technology ensures efficient production scheduling in both plants. Development of the hydrosulfite process and products typifies the steady change characteristic of the chemical industry. There is no marking time. Nothing stays the same.

And finally, to err is scientific

The name "hydrosulfite" conveys the mistaken notion that the compound contains hydrogen. Hydrosulfite should actually be known as sodium dithionite. By the time this mistake had been recognized, the brand name "Hydrosulfite Conc. BASF" had become so well-known commercially that it did not seem advisable to change the name to make it more scientifically correct.