New Production Process for Optical Fiber

Advertisement

As preforms, high-purity synthetic silica glass tubes are the basis for the production of high-quality and powerful optical fibers used in optical data transmission. Heraeus Tenevo AG has now introduced an innovative production process that will help fiber producers achieve much lower production costs. For, the "Online-RIC" technology allows the production of the extremely fine optical fibers out of big quartz glass cylinders in one single process step. The cost savings obtained are a decisive factor for staying competitive on the telecommunications market, which is characterized by overcapacities and an extreme drop in prices.

The new "Online-RIC" technology - RIC stands for "rod in cylinder" - is currently introduced worldwide to the fiber market. "Online" means that Heraeus Tenevo's silica glass cylinders, which make up roughly 95 percent of the later optical fiber, can now be fused directly with their customers' silica glass rods during drawing the fiber - at about 2,000 degrees Celsius and a draw speed of 100 to 120 kilometers per hour. Thus the production of optical fibers can now take place in only one process step. The cylinders used in the new process are much larger than the regular ones. While in the standard process one tube is sufficient to draw 400 kilometers of fiber, the new process provides fiber lengths of 2,000 to 5,000 kilometers.

Technology advantage strengthened for years with Online-RIC

After the pilot production phase, the experiences with the new technology of the U.S. fiber manufacturer and key customer OFS, formerly Lucent Technologies and also AT&T, are convincing: "As far as we now, the RIC process produces the world's largest preforms. RIC processing provides OFS with significant cost advantages going forward, and it is critical to the success of OFS's fiber business in the existing highly competitive optical fiber and cable market," says Dave Kalish, Chief Technical Officer and Vice President R & D with OFS Fitel.

With the new process, Heraeus Tenevo has underscored its prominent position as the world's market and technology leader in silica glass tubes for optical fibers and is one important step ahead of its competitors: "With Online-RIC we have established a new and already patented benchmark in optical fiber production, and we count on securing our technological advantage for several years," says the Chief Technical Officer of Heraeus Tenevo, Heinz Fabian. "The extreme cost pressure in the production of optical fibers also leads to a high pressure on the innovating capability to produce ever larger preforms at ever lower costs while maintaining the highest quality."

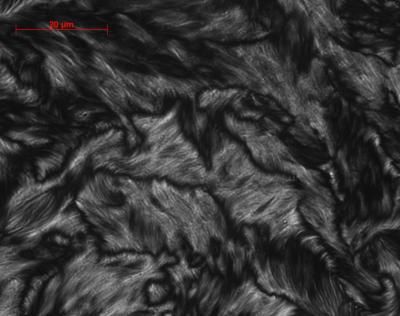

The demand for optical fibers is mostly driven by the expansion of the Internet. Until the end of 2003, more than 600 million kilometers of fibers were installed worldwide in total, and another 50 million kilometers will be added annually. The transfer of information via fiber optic cables is accomplished with laser light of a precisely defined wavelength that is conducted through the center of an optical fiber by attenuated total reflexion. It depends on the degree of purity and homogeneity of the silica glass how far the light signal can travel before amplification is needed. The highly pure silica glass fibers are in comparison as transparent as a long sight of 100 to 200 kilometers. Impurities in the silica glass amount to ten in one billion parts at the most.

Heraeus Tenevo AG, which is based in Hanau, Germany, and has production sites in Bitterfeld, Germany, and in Buford, Georgia, U.S.A., develops and produces synthetic silica glass of the highest purity, which is the starting material for optical fibers used in the transmission of information and data.