Cognis Innovation Award: new phytosterol production process

Global demand for phytosterols continues to grow, as manufacturers become aware of their versatility and the benefits they can bring. For example, they are added to margarine as cholesterol-reducing agents. Cognis is one of the world's leading producers of phytosterols, and has now developed a process for extracting them from the by-products of methyl ester production. Usable methyl esters also result from the process, whose creators were recognized by their employers with this year's gold Cognis Innovation Award.

Cognis's sterol production was previously part of the same edible oils refining process by which Vitamin E is produced, at its US plant. However, this methodology offered limited scope for increasing sterol production, so an international cross-functional team was set up to examine alternative methods.

The solution they arrived at was to use by-products of methyl ester production as a raw material. The project team, including staff from France, Germany and the USA, succeeded in developing a technique for converting the sterol esters that make up 20 to 30 percent of the by-products of methyl ester production into free sterols, and refining them. As a by-product of this multi-stage process, methyl esters are also produced, which can be used as bio diesel or a raw material for fatty alcohol production.

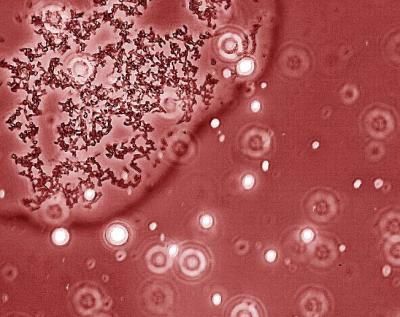

The stages of the new process include the chemical conversion of the sterols, purification and granulation. Working closely with customers from the food and pharmaceutical sectors, the team was able to ensure the end product is one that fully meets actual market requirements. Comments team member Bernhard Gutsche, head of Process Technology at Cognis Deutschland: "From the first day the production process went live, we have been achieving a sterol purity of up to 99 percent. Another key benefit is that the process does not involve GM oils at any stage, so the high-purity sterols we produce are perfectly suited for use in the food industry."

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

LANXESS plasticizers for toy and food contact applications approved

DKSH opens sales office in Sri Lanka and accomplishes major expansion into the Indian subcontinent

Final report: analytica Vietnam 2011 a successful exhibition

HW Technics B.V. - Rozenburg, Netherlands

Ashland announces production/distribution agreement with Boytek Resins of Turkey