BASF provides innovative catalyst for fuel cell vehicle

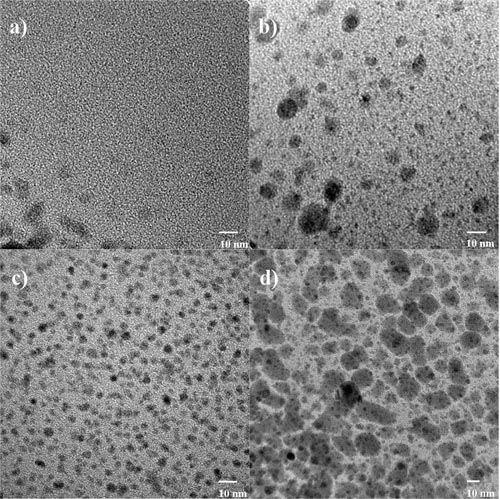

Catalytic converters in cars have long since become standard equipment for exhaust gas purification. But the NECAR 5 (New Electric Car), DaimlerChrysler AG's fuel cell car that is being presented today, uses an innovative catalyst made by BASF that has a completely different function: it is a key component in the so-called Methanol reformer. This is where hydrogen is released from the methanol and is fed to a fuel cell. BASF has developed this high-performance catalyst in an exclusive cooperation with XCELLSIS, a joint venture of DaimlerChrysler, Ballard Power Systems, Inc. of Vancouver (Canada), and the Ford Motor Company of Dearborn, Michigan (United States). Three years ago, BASF had developed the catalyst for methanol reforming for the NECAR 3, the prototype of DaimlerChrysler's methanol-powered fuel cell vehicle. In the intervening time, BASF researchers have improved the catalyst and made it considerably more active, compact and stable.

"Methanol paves the way to the environmentally friendly technology of the future, namely, fuel cell drives for vehicles," explains Dr. Markus Hölzle, who is in charge of further developig BASF's catalyst. "In the medium term, I do not see any other solution for the market at large. After all, alternative concepts where pure hydrogen is used instead of methanol pose a number of unresolved problems." For instance, complicated pressure tanks or cryogenic tanks are needed to store the hydrogen gas in the vehicle.

Filling comfortable and simple, much less carbon dioxide in the exhaust gas

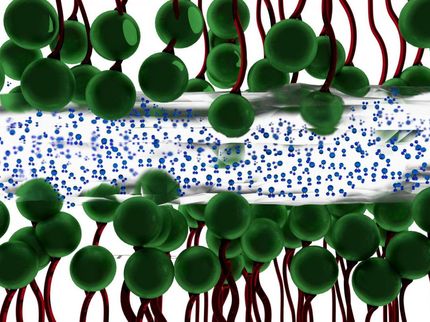

This is different with methanol: the fuel used by the NECAR 5 can be filled into the tank just as easily as gasoline or diesel. From a chemical standpoint, methanol is the simplest alcohol and nowadays is obtained almost exclusively from natural gas. It is also conceivable to extract this substance from waste or from renewable raw materials. The hydrogen needed by the fuel cell is generated from methanol right in the NECAR 5. To this end, the alcohol is evaporated together with water and fed into the reformer. Here, the mixture is contacted with the BASF catalyst consisting of copper oxide and other metal oxides. At an operating temperature ranging from 200°C to 350°C, methanol and water are converted into hydrogen and carbon dioxide. The gas mixture is then employed in the fuel cell to generate electric power. All in all, this process generates considerably less carbon dioxide than internal combustion engines.

A new development for the NECAR 5 is the ATR reactor (this abbreviation stands for autothermal reforming). This "starter" - likewise containing BASF's catalyst - allows the car to start cold. Here, the methanol, together with water and air, is partly reformed into hydrogen and partly combusted. This quickly brings the drive system up to the right operating temperature, as with diesel vehicles in the past.

BASF is making preparations for commercial-scale production of the catalyst

The development of high-performance catalysts as reaction accelerators for industrial processes is one of BASF's core areas of expertise. However, whereas catalysts are normally designed to yield optimal results within narrow pressure and temperature ranges, the challenge in the case of methanol reforming is to achieve flexibility. For the fuel cell vehicle to manage without back-up storage elements such as batteries or hydrogen tanks, the reformer must r

Other news from the department

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.