Tungsten makes it happen

Saving energy in one of the most important chemical processes.

Advertisement

Alkenes, such as ethylene and propylene, are important starting materials for chemical industry. One of the technical processes for the manufacture of alkenes is the catalytic dehydration of the corresponding alkanes. This process could be made much more profitable if a new formulation, developed by researchers in the Netherlands, can be put into practice. In order to turn an alkane into an alkene, two hydrogen atoms must be removed. This requires a lot of energy and results in a low yield. One way around this could be to couple this reaction with a second process: the Oxidation of the freed hydrogen with oxygen to form water could deliver the required energy. At the same time, the removal of the hydrogen from the reaction mixture could increase the yield of the conversion.

However, this requires a catalyst system that allows for the selective oxidation of hydrogen in the presence of alkanes and alkenes -- and that doesn't sinter and become deactivated at the required high temperatures. A research group at the University of Amsterdam has now developed such a catalyst system.

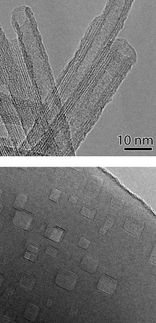

Cerium oxides and mixed oxides are currently used as a sort of solid oxygen exchanger in various applications. Gadi Rothenberg, Bart de Graaf, and Alfred Bliek thus selected cerium oxide as their starting point. Pure cerium oxide demonstrates no selectivity whatsoever for the oxidation of hydrogen. However, its selectivity can be varied by the addition of other metal ions. The reason for this is the disruption to the crystal structure caused by foreign ions with different sizes or charges. In a parallel synthesis, the researchers produced a set of ten different cerium mixed oxides, in each of which 10% of the cerium ions were replaced by another metal. In subsequent tests, tungsten was shown to be the dopant of choice, demonstrating a 97% selectivity for hydrogen. On the other hand, alkenes and alkanes did not react with the oxygen atoms in the cerium-tungsten mixed oxide.

After the reaction, the "holes" left in the crystal lattice by the missing oxygen atoms can easily be filled with a stream of oxygen. The cycle can be repeated many times before this solid "oxygen warehouse" sinters, cokes, or loses activity for some other reason.

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.