Microbes as an Energy Source

A new generation of microbial fuel cells demonstrates amazingly high current density

fuel cells could be the energy source of the future for many applications, including in vehicles. The direct transformation of chemical to electrical energy without a detour involving combustion is what makes this technology so environmentally friendly. The breakthrough into broad usage hasn't happened yet, but some clever minds are already contemplating novel concepts for the generation after next. These future systems could even work using self-regenerating raw materials -- microbial fuel cells. Researchers from Greifswald University have now reached an important milestone on the way toward such bio-fuel cells.

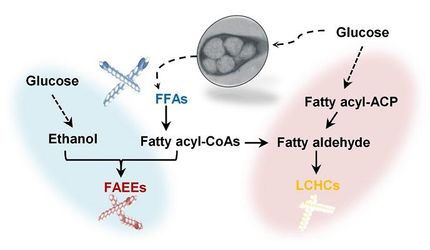

While "normal" fuel cells use conventional energy sources like methanol, bio-fuel cells make use of the metabolic activity of microorganisms to produce energy. This ingenious concept has thus far failed in practice because the resulting current has been much too low. This stems from the decidedly difficult task of "wiring" the microbes to the circuit. Uwe Schröder, Juliane Nießen, and Fritz Scholz have now developed a new process for delivering the electrons "tapped" from microbial metabolism to the electrodes. While the microorganisms happily metabolize away in their tank of glucose, the fermentation solution is continuously pumped through a separate anode chamber. The anode compartment is separated from the cathode chamber by a semipermeable membrane. Nothing unusual so far.

The secret of this bio-fuel cell lies in its novel layered anode. A platinum electrode or platinum-coated graphite electrode is coated with a layer of the electrically conducting polymer polyaniline. This layer of plastic has it all; it is biocompatible and electrocatalytically active. It takes electrons from the bacterial metabolism and transfers them to the anode, thus playing an active role in the flow of current. But that is still not all. During operation of the cell, the products of the bacterial metabolism, as well as side-products of the electrocatalytic oxidation process are formed. These accumulate on uncoated anodes and quickly deactivate them. The plastic coating noticeably slows this process, though it cannot completely prevent it. This problem is solved by a further trick; the deposits are chemically converted and dissolved away from the anode surface by means of regular voltage pulses.

"Our novel bio-fuel cell continually produces up to 1.5 mA/cm2," reports Schröder. "We have thus successfully stepped from the micro- into the milliampere range."

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

BRC - Berghof Reactor Controller by Berghof

BRC - complete package for data acquisition, storage and control of all process parameters

Touch controllers are easy to use and provide quick access to all important functions

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.