DuPont to Serve as Founding Partner of New Institute for Soldier Nanotechnologies at MIT

Advertisement

DuPont will be serving as a founding partner of the new Institute for Soldier Nanotechnologies, which today officially opened its 28,000-square-foot research and development facility at the Massachusetts Institute of Technology (MIT).

The U.S. Army Research Office and MIT recently initiated the Institute for Soldier Nanotechnologies (ISN) -- a $50 million and 150-person initiative that will serve as the Army's center of expertise in the application of nanotechnology. The ISN's goal will be to increase the "protection and survivability" of U.S. soldiers with new technologies that target six priorities: threat detection, threat neutralization, automated medical treatment, concealment, enhanced human performance and reduced logistical footprint. Reducing logistical footprints are especially important to an in- field soldier whose standard-issue gear now weighs upwards of 100 pounds. The goal is reducing the load to about 45 pounds.

The high-tech uniforms and gear are the key components of the U.S. Department of Defense's vision for flexible, self-sufficient soldiers who could be quickly inserted into rugged and unpredictable terrain such as Afghanistan.

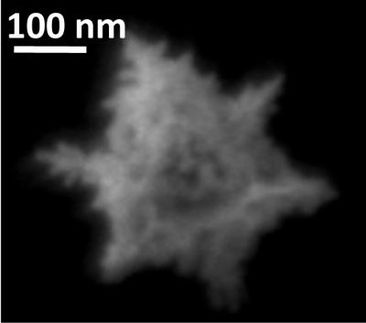

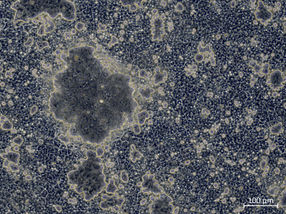

DuPont participated in the initial proposal for the ISN and was selected as a founding industrial partner. DuPont is exploring nanotechnology and developing protective lightweight molecular materials to equip the U.S. soldier of the future with uniforms and gear that help protect them, shield them and heal them in the field. Specifically, DuPont researchers are developing revolutionary nanotechnology-based materials that can be used in field-ready products, including innovative and protective lightweight uniforms and "smart" gear. A few examples of "smart" functionality that may be explored are materials that:

-- change colors on command to camouflage in changing environments

- even manipulate light to make soldiers invisible in the field.

-- change a shirtsleeve into a splint or a pant leg into a rigid cast in the field if a soldier is injured.

-- possess built-in sensors so that each soldier's physical conditions and location in battlefields can be monitored at distant command posts.

-- weave radio communications materials directly into the uniform's fabric -- providing soldiers flexibility and lighter loads.

-- automatically administer medicines and transmit vital signs to distant medics

-- provide impact protection materials and systems including ballistic and shrapnel.

-- provide chemical and biological protection materials and systems.

Other ISN industrial partners are Raytheon, Partners Healthcare, Dow Corning, Triton Systems, Dendritic Nanotechnologies, Nomadics, Carbon Nanotechnologies, and W.L. Gore and Associates.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.