Dow Completes First-Phase Expansion of Production Facility for LUMATION Light-Emitting Polymers (LEPs)

The Advanced Electronic Materials (AEM) business of The Dow Chemical Company recently completed the first phase of an expansion to its commercial manufacturing facility for LUMATION* Light-Emitting polymers (LEPs) at its Michigan Operations site (Midland, Mich.). These materials are essential to the production of polymeric light-emitting diode (pLED) displays, a next-generation display technology.

"As the development partner of choice in the pLED industry, Dow is committed to helping display manufacturers and OEMs successfully commercialize emissive display applications," said Dave Kyle, senior marketing manager for the AEM Display Technologies group. "With this facility, our customers can be confident we are a reliable source of supply for display technology materials, helping them to accelerate their speed-to-market for pLED displays. "

The first phase of the expansion is a multi-reactor facility that expands Dow's capacity to produce a broad portfolio of materials and products, including numerous colors and formulations of LUMATION LEPs.

"Dow collaborates with our customers to develop tailored solutions for their specific needs, so we designed the expansion to allow production flexibility and versatility," said Jim O'Brien, technical project director for the AEM Display Technologies group. "We can now efficiently supply LUMATION LEPs designed for our customers' specialized display application and fabrication processes, such as LEP products of specific molecular weights and grades tuned for passive- and active-matrix use."

Within the vertically integrated facility completed in the first phase of the expansion, Dow oversees the entire production process for LUMATION LEPs - allowing customers to focus on their pLED development and commercialization programs. Dow's capabilities include solution and ink formulation, ultra-filtration and packaging within a clean-room environment, for direct supply to pLED display fabrication lines around the world.

Dow expects to bring the second phase of the multi-million dollar expansion online in the second half of 2003. The second phase will further increase the production capacity for LUMATION LEPs, positioning Dow to meet global demand for LEPs for the next decade.

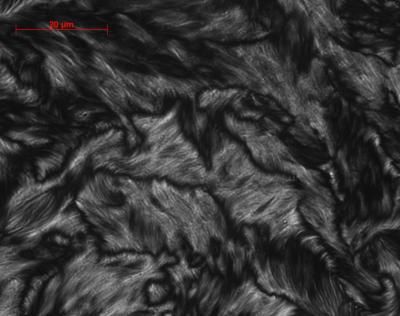

The first red, green and blue LUMATION LEPs are now available, enabling the manufacture of monochromatic and first-generation full-color pLED displays. LEPs such as those produced by Dow are the critical light-emitting material in an emissive display and provide many advantages over incumbent display technologies, such as traditional liquid-crystal displays (LCDs). pLEDs are one class of organic light-emitting diodes (OLEDs), a new display technology platform for producing bright, high-contrast, low-voltage emissive displays.

Most read news

Topics

Organizations

Other news from the department research and development

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

Spinsolve Benchtop NMR by Magritek

Spinsolve Benchtop NMR

Spinsolve is a revolutionary multinuclear NMR spectrometer that provides the best performance

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.