Printing low-cost flexible, stretchable electronics

Advertisement

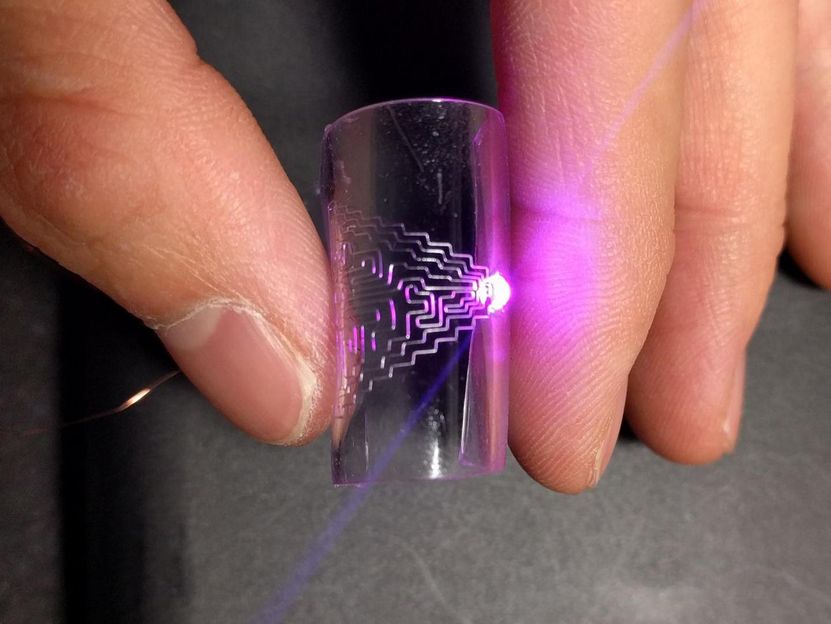

Researchers from North Carolina State University have developed a new technique for directly printing metal circuits, creating flexible, stretchable electronics. The technique can use multiple metals and substrates and is compatible with existing manufacturing systems that employ direct printing technologies.

This prototype demonstrates the potential of a new technique for printing flexible, stretchable circuits.

Jingyan Dong, North Carolina State University

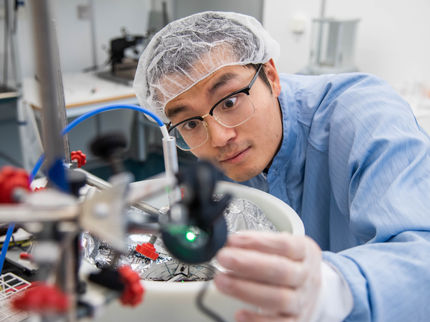

"Flexible electronics hold promise for use in many fields, but there are significant manufacturing costs involved - which poses a challenge in making them practical for commercial use," says Jingyan Dong, corresponding author of a paper on the work and an associate professor in NC State's Edward P. Fitts Department of Industrial & Systems Engineering.

"Our approach should reduce cost and offer an efficient means of producing circuits with high resolution, making them viable for integrating into commercial devices," Dong says.

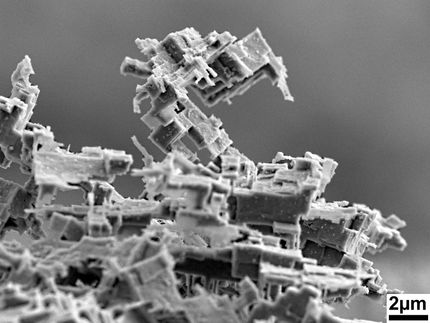

The technique uses existing electrohydrodynamic printing technology, which is already used in many manufacturing processes that use functional inks. But instead of ink, Dong's team uses molten metal alloys with melting points as low as 60 degrees Celsius. The researchers have demonstrated their technique using three different alloys, printing on four different substrates: one glass, one paper and two stretchable polymers.

"This is direct printing," Dong says. "There is no mask, no etching and no molds, making the process much more straightforward."

The researchers tested the resilience of the circuits on a polymer substrate and found that the circuit's conductivity was unaffected even after being bent 1,000 times. The circuits were still electrically stable even when stretched to 70 percent of tensile strain.

The researchers also found that the circuits are capable of "healing" themselves if they are broken by being bent or stretched too far.

"Because of the low melting point, you can simply heat the affected area up to around 70 degrees Celsius and the metal flows back together, repairing the relevant damage," Dong says.

The researchers demonstrated the functionality of the printing technique by creating a high-density touch sensor, fitting a 400-pixel array into one square centimeter.

"We've demonstrated the resilience and functionality of our approach, and we're open to working with the industry sector to implement the technique in manufacturing wearable sensors or other electronic devices," Dong says.

Original publication

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.