New microscope sets a record for visualizing surface wetting properties

wetting is an everyday phenomenon that represents how well liquid spreads on a surface. When water comes into contact with an extremely water-repellent, or 'superhydrophobic' surface, droplets bead up and roll off easily. Aalto University researchers have developed a measurement technique called Scanning Droplet adhesion Microscopy (SDAM) to understand and characterize the wetting properties of superhydrophobic materials.

"Our novel microscope will promote the understanding of how wetting emerges from surface microstructures. The measuring instrument can also detect microscopic defects of the surface, which could allow coating manufacturers to control the quality of materials. Defects in self-cleaning, anti-icing, anti-fogging, anti-corrosion or anti-biofouling products can impeach the functional integrity of the whole surface," explains Professor Robin Ras from Aalto University School of Science.

SDAM is extremely sensitive and 1000 times more precise than the current state-of-the-art wetting characterization methods. It also has the ability to measure minuscule features and inconsistencies of surfaces with microscale resolution. Existing instruments for measuring droplet adhesion forces only detect forces down to a micronewton level - not sensitive enough for superhydrophobic surfaces.

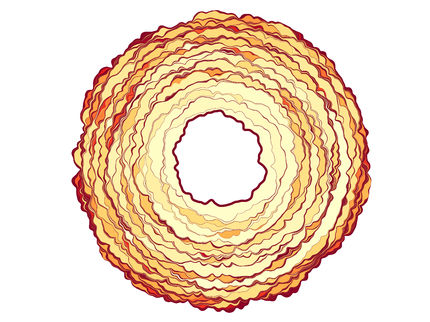

"We have used a droplet of water to measure the water-repellent properties of a surface by recording the very tiny nanonewton force when the droplet touches the surface and when it separates from the surface. By measuring on many locations with micrometer spacing between the measurement points, we can construct a two-dimensional image of the surface's repellency, called a wetting map," explains Professor Quan Zhou from Aalto University School of Electrical Engineering.

Wetting maps are a new concept for hydrophobic surface characterization and open a window for investigating structure-property relationships in surface wetting.

Up to now, 'contact angle measurement' has been the typical method of measuring wetting properties of surfaces. It is prone to inaccuracies, though, for surfaces that are highly repellent to liquid. Unlike contact angle measurement, SDAM does not require a direct line of sight, which allows measuring uneven surfaces such as fabrics or biological surfaces. SDAM can also detect wetting properties of microscopic functional features that were previously very hard to measure. Those microscopic features are important in many biochips, chemical sensors and microelectromechanical components and systems.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.