Innovative Extraction Technologies

Getting More From Biomass

Swedish-Finnish company Stora Enso is undergoing a renewable materials transformation. Previously focused on pulp and paper, the company is developing new, innovative products and services based on wood and other non-food competing feedstock. The goal – to replace non-renewable materials and use raw materials more efficiently. New technologies are enabling Stora Enso to extract hemicellulose, sugars and Lignin more efficiently from biomass.

Stora Enso Biomaterials division employees working in the lab

Stora Enso

Forest landscape in Finland

Stora Enso

Set up in 2012, the Stora Enso Biomaterials division is focused on creating a new business platform, based on biomass, which does not compete with food production. Working on technology development and commercialisation of lignin and other bio-based chemical intermediates, the Biomaterials division is at the forefront of new biotechnology approaches.

Valuable lignin

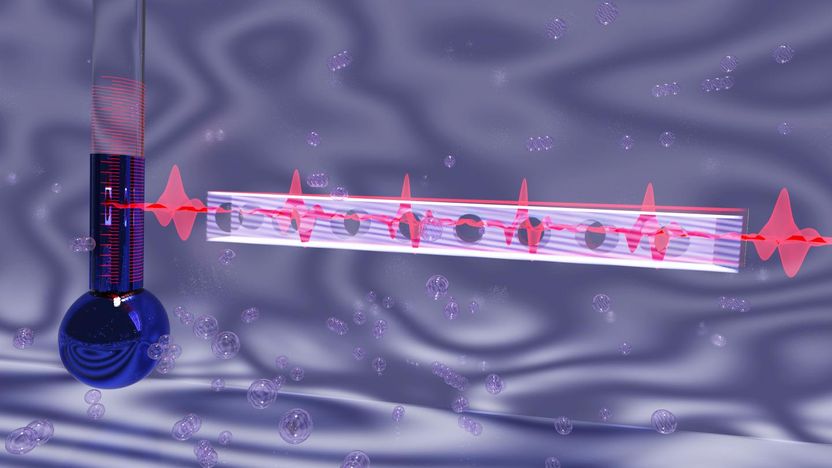

Stora Enso has been commercialising lignin since 2013, when it invested €32 million in new lignin separation technology at its Sunila mill in Finland. Using LignoBoostTM technology, Sunila has been producing dried Kraft lignin since 2015, where the lignin production capacity is 50,000 tonnes.

In a pulp mill, cooking chemicals which are used to extract cellulose fibres from wood are recycled in the recovery line. Black liquor contains cooking chemicals (white liquor) and wood residues, comprised mostly of lignin. In the recovery boiler, chemicals are recovered and the rest – mainly lignin – is burned for energy.

At Sunila, Stora Enso extracts part of the lignin from the black liquor before it goes to the recovery boiler. After extraction and pressing, the lignin is then dried in a ring dryer – to achieve 95% dry content – then packed. Currently, Stora Enso’s lignin is also burned in lime kilns at Sunila to generate energy, which has dramatically reduced the mill’s carbon emissions. Sunila is now running practically fossil-free in normal operations.

While the pulp and paper industry has normally discarded lignin, Stora Enso sees its strong potential. A versatile, non-toxic polymer, lignin offers many opportunities to replace fossil-based materials. For example, refined lignin can be a replacement for oil-based phenolic materials which are used in resins for adhesives e.g. in plywood, veneer applications, laminates and insulation material. In the future, Stora Enso foresees lignin development for carbon fibre applications.

Testing extraction technologies in the US

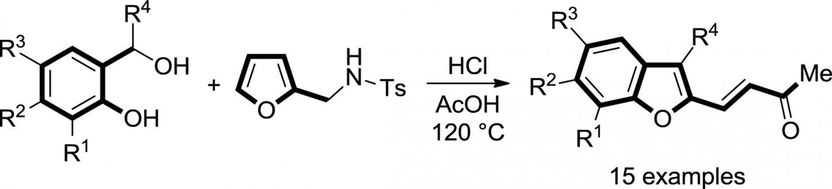

Another substantial investment made by Stora Enso occurred in 2014, when the company acquired extraction technology from US biotechnology firm Virdia for €32 million. In Raceland, Louisiana, USA, a demonstration and market development plant is set to come online later this year to test the technology. Using waste sugarcane bagasse as feedstock, Raceland will convert cellulosic biomass into highly-refined C5 sugars (xylose). Xylose can be transformed into xylitol, which is widely used in food and oral care applications.

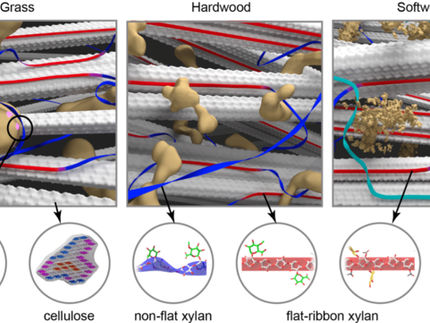

In a first phase, the Raceland facility will extract a high-purity xylose sugar stream. Once proven, the technology can also be integrated into existing pulp mills. Extracted material brings extra value and improves bottlenecks in the existing pulp-making process. In the future, the technology will extract different fractions from wood and other biomass, leading to cellulose fibres, C5 sugars, C6 sugars and lignin.

Another substantial investment made by Stora Enso occurred in 2014, when the company acquired extraction technology from US biotechnology firm Virdia for €32 million. In Raceland, Louisiana, USA, a demonstration and market development plant is set to come online later this year to test the technology. Using waste sugarcane bagasse as feedstock, Raceland will convert cellulosic biomass into highly-refined C5 sugars (xylose). Xylose can be transformed into xylitol, which is widely used in food and oral care applications.

In a first phase, the Raceland facility will extract a high-purity xylose sugar stream. Once proven, the technology can also be integrated into existing pulp mills. Extracted material brings extra value and improves bottlenecks in the existing pulp-making process. In the future, the technology will extract different fractions from wood and other biomass, leading to cellulose fibres, C5 sugars, C6 sugars and lignin.

Doing more – with less

It is clear that sustainable, renewable biomass offers a lot of opportunities. This is why Stora Enso recently inaugurated the Innovation Centre for Biomaterials in Stockholm. Identifying business opportunities in the renewable materials market and linking them with leading innovation and research centres in business and academia, the Innovation Centre will speed up delivery of commercial solutions to customers.

As well as researching applications for lignin and xylose, work at the Innovation Centre is also currently focused on MFC (a special cellulose material produced by processing cellulose fibres mechanically into fibrils) and alternative textile solutions such as making viscose-type fibres more sustainable.

The bioeconomy is growing and Stora Enso will continue to expand its biomaterials focus. By investing in innovative technologies, Stora Enso knows more can be extracted from wood and other non-food competing biomass to create a range of high-performance, bio-based products. Confident in its timely renewable materials shift, Stora Enso knows the future is bio-based.

By Kirsi Seppäläinen, SVP Communications, Stora Enso Biomaterials division

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Extraction

Extraction is a fundamental process in the chemical laboratory that enables specific components to be isolated and concentrated from a mixture. Whether it's extracting active ingredients from natural products, removing impurities from synthesis products, or preparing analytical samples, extraction is a key step in achieving precise and efficient results in chemical research and analysis.

Topic world Extraction

Extraction is a fundamental process in the chemical laboratory that enables specific components to be isolated and concentrated from a mixture. Whether it's extracting active ingredients from natural products, removing impurities from synthesis products, or preparing analytical samples, extraction is a key step in achieving precise and efficient results in chemical research and analysis.