Air Products and Johnson Matthey Establish Alliance to Market Monolith Catalyst Technology to Fine and Specialty Chemical Produc

Advertisement

Air Products and chemicals, Inc. announced that a Marketing Agreement has been signed with Johnson Matthey to commercialize its proprietary monolith catalyst-based process technology: the Monolith Loop Reactor (MLR). The technology has been developed specifically for the specialty chemicals market.

Air Products has developed a unique and economical process solution that brings many of the advantages of fixed bed catalytic processes to the smaller-scale chemical producer. The combination of the attributes and robustness of the MLR technology along with the catalyst capabilities of Johnson Matthey provides a unique new technology package for the chemical manufacturer. Initial market focus will be to companies who operate hydrogenation reactors utilizing precious metal catalysts.

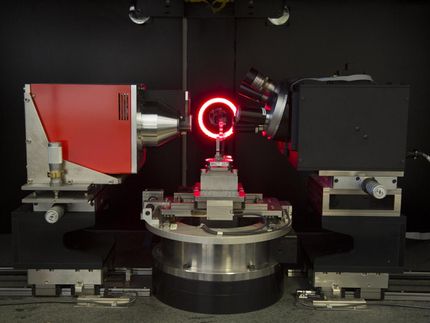

The MLR is a novel integrated monolith catalyst reactor system and can be easily retrofitted onto existing commercial slurry-catalyst stirred tank reactors. The slurry catalyst is replaced with a reusable high-activity monolithic catalyst bed. A two-phase gas and liquid feed mixture is fed to the reactor using a specialized gas-liquid ejector. This technology provides reaction rates that are 10 to 100 times greater than typical reaction rates in the slurry tank reactor for many process chemistries. The monolith catalyst effectively concentrates or intensifies the catalytic reaction in the small parallel channels of the monolith, while the ejector correspondingly increases the gas-liquid mass transfer to match these high reaction rates. The MLR technology provides a host of improvements in the areas of process economics, hygiene, post-processing options, controlling catalyst contact at selected times in the batch cycle and incremental productivity expansion by the elimination of slurry catalysts and filtration unit operations.

Under the terms of this agreement, Johnson Matthey will be the exclusive supplier of a new line of catalysts developed for use with Air Products' MLR process technology. To sustain the rapid adoption of the technology, state-of-the-art support facilities have been developed and include high throughput laboratories and a pilot-scale MLR installation to quickly screen and optimize MLR-based process modules. Similar capabilities have been implemented to rapidly develop and manufacture custom catalyst modules required for the diverse range of syntheses operated by chemical manufacturers.

Most read news

Topics

Organizations

Other news from the department research and development

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.