Tunneling a path to low cost, high efficiency solar cells

Lowering the cost of solar cell production and making it more affordable to individuals and businesses could be a game-changer for the energy sector.

That is one of the reasons behind the U.S. Department of Energy's 2011 launch of the SunShot Initiative, a national effort to drive down the cost of solar electricity and support solar adoption.

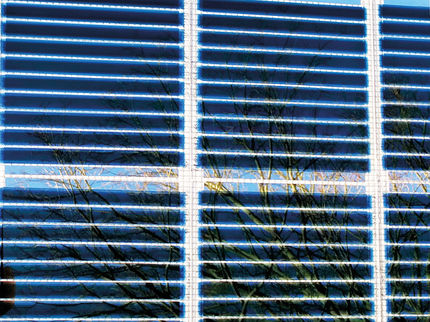

An important area of focus for this effort is photovoltaic (PV) research and development. Solar cells consist of a photovoltaic material - a substance that can transform sunlight into electricity. Traditional methods of producing the photovoltaic material requires many steps and a lot of energy to make, driving up the cost.

According to Nicholas C. Strandwitz , assistant professor of materials science and engineering at Lehigh University , one path to reducing the cost of solar cells is to reduce the amount of energy it takes to process silicon into a solar cell.

Strandwitz was recently awarded a grant as part of the SunShot Initiative's Photovoltaics Research and Development 2 funding program, which seeks to transform PV module design, explore high-risk emerging technology research, and devices and designs that facilitate rapid solar installation. Projects under this program will investigate new solar technology innovations that have the potential to make solar power affordable throughout the United States.

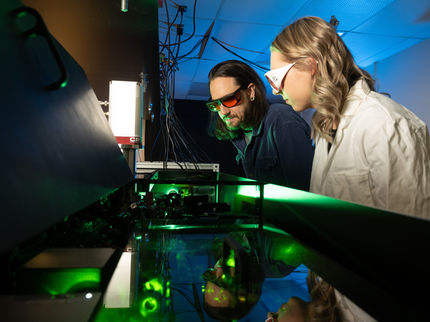

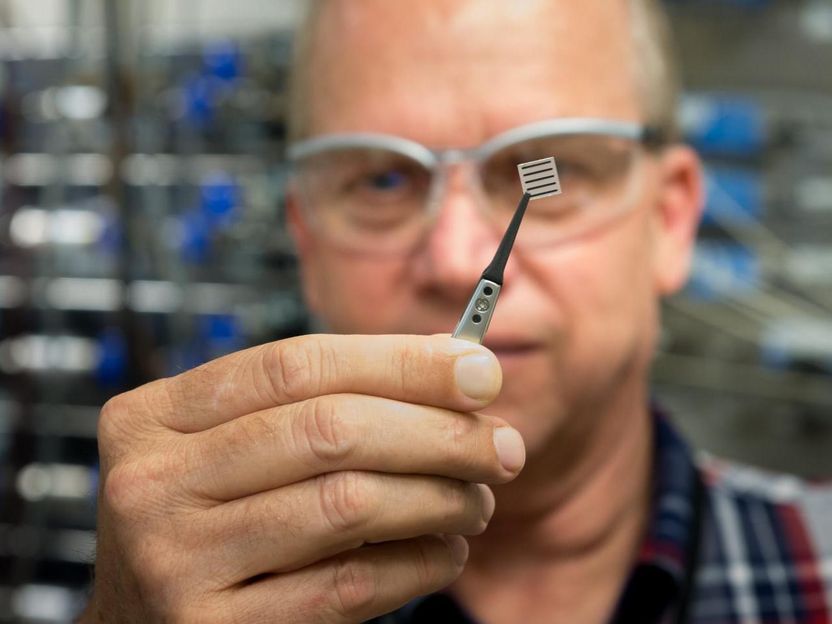

Strandwitz will explore a promising technique to manufacture solar cells using atomic layer deposited (ALD) tunnel barriers, which are barriers that are so thin, electrons can literally "tunnel" through them. He and his team will quantify the electronic behavior of silicon cells made with this ALD tunnel barrier combined with metal oxide materials that selectively transport electrons with specific energies.

According to Strandwitz, the creation of thin film layers and interfaces with the right electronic properties can result in high efficiency photovoltaics, while decreasing the cost of production.

"Controlling interfaces and directing electron flow is essential for creating efficient solar cells," says Strandwitz.

He and his team will quantify the electronic behavior of these contacts, which may constitute some of the most efficient electrical contacts to silicon photovoltaics to date.

"ALD can grow 1 nanometer-thick films very reliably, making it a controllable and scalable way to control the properties of the silicon surface," says Strandwitz. "This ALD fabrication technique could make next generation solar cells more efficient and, ultimately, more inexpensive to manufacture."

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Why mercury is more dangerous in oceans

Sensor stickers transform the human body into a multi-touch surface

BASF to start up new FCC catalysts testing and research laboratory in Heidelberg

New bar for water-splitting, CO2-splitting techniques set

Agilent Technologies Instruments Selected by South African Doping Control Laboratory for 2010 World Cup

Triruthenium_dodecacarbonyl

Honeywell and U.S. Display Consortium to Jointly Develop New Flat Panel Display Materials

New Guideline: Determination of polycyclic aromatic hydrocarbons (PAH) - GC/MS method

A new way to control oxygen for electronic properties