New bar for water-splitting, CO2-splitting techniques set

Advertisement

Researchers from North Carolina State University have significantly boosted the efficiency of two techniques, for splitting water to create hydrogen gas and splitting carbon dioxide (CO2) to create carbon monoxide (CO). The products are valuable feedstock for clean energy and chemical manufacturing applications.

The water-splitting process successfully converts 90 percent of water into hydrogen gas, while the CO2 -splitting process converts more than 98 percent of the CO2 into CO. In addition, the process also uses the resulting oxygen to convert methane into syngas, which is itself a feedstock used to make fuels and other products.

"These advances are made possible by materials that we specifically designed to have the desired thermodynamic properties for each process," says Fanxing Li, an associate professor of chemical and biomolecular engineering at NC State who is corresponding author of two papers on the work. "These properties had not been reported before unless you used rare earth materials."

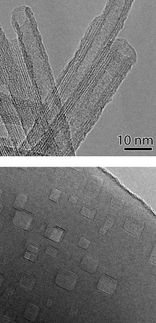

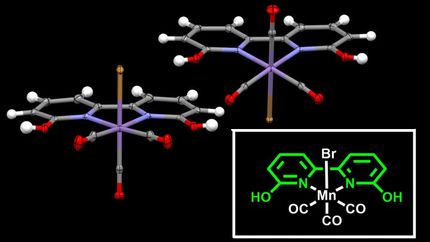

For the CO2 -splitting process, researchers developed a nanocomposite of strontium ferrite dispersed in a chemically inert matrix of calcium oxide or manganese oxide. As CO2 is run over a packed bed of particles composed of the nanocomposite, the nanocomposite material splits the CO2 and captures one of the oxygen atoms. This reduces the CO2 , leaving only CO behind.

"Previous CO2 conversion techniques have not been very efficient, converting well below 90 percent of the CO 2 into CO," Li says. "We reached conversion rates as high as 99 percent.

"And CO is valuable because it can be used to make a variety of chemical products, including everything from polymers to acetic acid," Li says.

Meanwhile, the oxygen captured during the CO2 -splitting process is combined with methane and converted into syngas using solar energy.

For the water-splitting process, researchers created iron-doped barium manganese oxide particles. Other than the difference in materials, the process is remarkably similar. As water - in the form of steam - is run over a bed of the particles, the iron-doped barium manganese oxide splits the water molecules and captures the oxygen atoms. This leaves behind pure hydrogen gas.

"Our conversion here is 90 percent, which compares very favorably to other techniques - which are often in the 10-20 percent range," says Vasudev Haribal, a Ph.D. student at NC State and lead author of the paper on the water-splitting work.

The oxygen captured during the water-splitting process is used to make syngas, using the same technique used in the CO2 -splitting process.

"We think both of these materials and processes represent significant steps forward," Li says. "They use relatively inexpensive materials to efficiently extract valuable feedstock from resources that are either readily available (in the case of water) or are actually greenhouse gases (in the cases of CO2 and methane).

"We are now working on developing materials that are even more efficient," Li says. "And we're open to working with outside groups who are interested in scaling these processes up for manufacturing."

Original publication

Vasudev Pralhad Haribal , Feng He , Amit Mishra , Fanxing Li; "Iron‐Doped BaMnO3 for Hybrid Water Splitting and Syngas Generation"; ChemSusChem; 2017

Zhang, Junshe and Haribal, Vasudev and Li, Fanxing; "Perovskite nanocomposites as effective CO2-splitting agents in a cyclic redox scheme"; Science Advances; 2017