2-D layered devices can self-assemble with precision

Squid-inspired proteins can act as programmable assemblers of 2D materials, like graphene oxide, to form hybrid materials with minute spacing between layers suitable for high-efficiency devices including flexible electronics, energy storage systems and mechanical actuators, according to an interdisciplinary team of Penn State researchers.

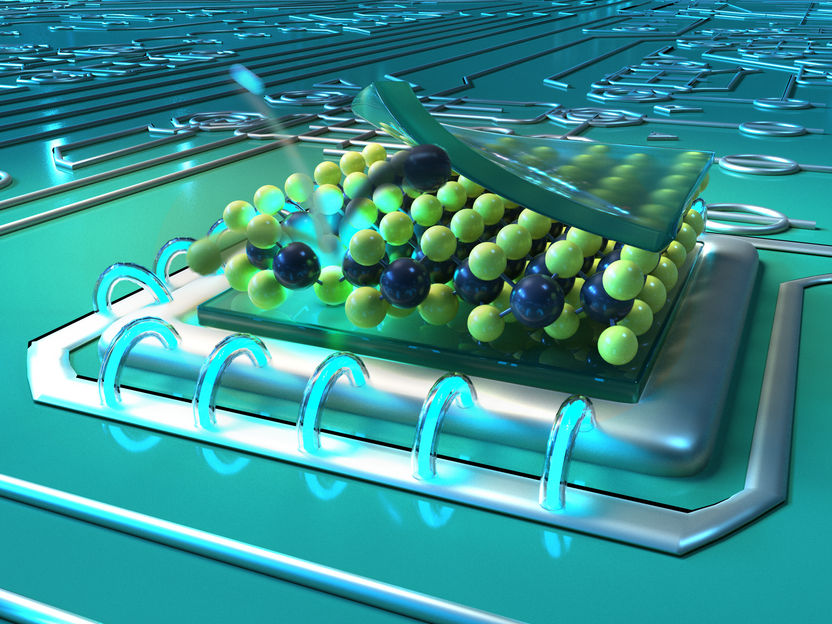

Single molecule-high sheets of graphene oxide mix in solution with synthetic tandem repeat proteins patterned on squid ring teeth. The two separate materials self assemble so that the tandem repeat proteins attach to the edges of the graphene oxide sheets -- one end on a sheet -- to bring the graphene into stacks and uniformly space the sheets. The amount of spacing between graphene oxide sheets is determined by the length of the tandem repeat protein.

Penn State

"2D layered materials can be made by vacuum (chemical vapor) deposition," said Melik C. Demirel, Pierce Development Professor and professor of engineering science and mechanics . "But the process is expensive and takes a long time. With chemical vapor deposition the problem also is we can't scale up."

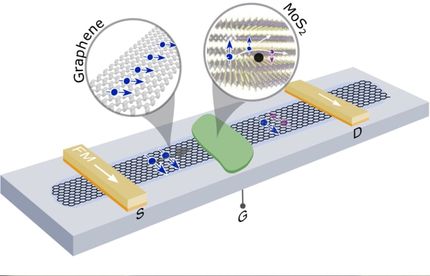

Materials like graphene oxide are composed of single layers of molecules connected in a plain. While the length and breadth of the sheet can be anything, the height is only that of one molecule. To make usable composites and devices, 2D materials must be stacked either in piles of identical sheets or combinations of sheets of different composition stacked to specification. Together with Mauricio Terrones, professor of physics, chemistry and materials science and engineering, and director of 2D Atomic Center, Penn State, Demirel and his team are currently looking at stacking sheets of identical materials using a solvent approach that self assembles.

"Using the solvent approach the molecules are self-assembling, self-healing and flexible," said Demirel. "Currently we are stacking identical layers, but they don't have to be the same."

To make these molecular composites using solvent technology, the researchers combined the sheets of graphene oxide with synthetic polymers patterned after proteins found in squid ring teeth. One end of the protein strand attaches to the edge of a graphene oxide sheet and the other end attaches to the edge of another graphene dioxide sheet. The sheets of graphene oxide self-assemble to stack up with proteins linking the edges of the sheets. The length of these tandem repeat proteins -- their molecular weight -- determines the distance between sheets.

"Up until now, no one has been able to stack composite layers closer than 1 nanometer," said Demirel. "We can stack them at atomistic precision with 0.4, 0.6 or 0.9 nanometer resolution by choosing the right molecular weight of the same protein. Respectively."

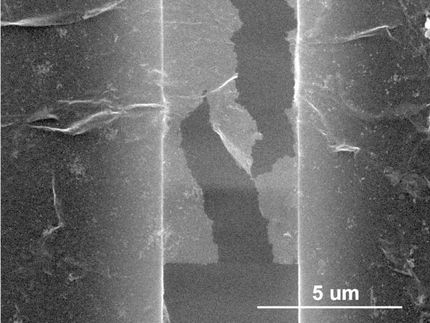

The researchers tested this material's ability to make tiny devices by creating bimorph thermal actuators. A bimorph activator is a small piece of material made from two different layers and placed perpendicular to a surface. When activated, usually by an electric current, the bimorph actuator bends from the perpendicular.

The researchers report that "these novel molecular composite bimorph actuators can facilitate thermal actuation at voltages as low as about 2 volts, and they boast energy efficiencies 18 times better than regular bimorph actuators assembled using bulk graphene oxide and tandem repeat films." They believe that higher molecular weight proteins could reach much higher displacements.

Original publication

Original publication

Mert Vural and Yu Lei and Abdon Pena-Francesch and Huihun Jung and Benjamin Allen and Mauricio Terrones and Melik C. Demirel; "Programmable molecular composites of tandem proteins with graphene oxide for efficient bimorph actuators"; Carbon; 2017

Topics

Organizations

Other news from the department science

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.