Fixation of powder catalysts on electrodes

Chemists at Ruhr-Universität Bochum have developed a new method to tightly fix catalyst powders on electrode surfaces. Currently, the high physical stress induced on catalyst films by gas evolving reactions hampers the application of powder based catalysts. The developed technique is potentially interesting for hydrogen production by water electrolysis. A team involving Dr Corina Andronescu, Stefan Barwe and Prof Dr Wolfgang Schuhmann from the Center for Electrochemical Sciences reports on this.

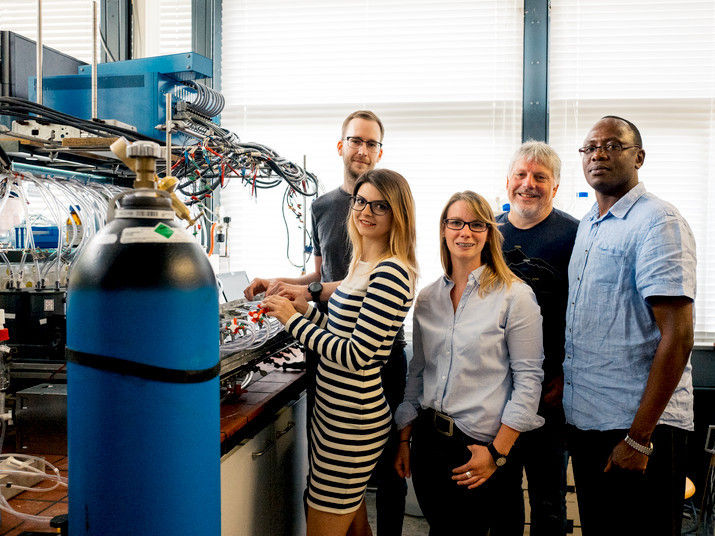

The team at the Center for Electrochemical Sciences at Ruhr-Universität Bochum: Stefan Barwe, Dr Corina Andronescu, Sandra Möller, Prof Dr Wolfgang Schuhmann and Dr Justus Masa (from left to right). The home-made apparatus shown in the background allows the scientists to simultaneously explore the long-term stability of up to ten catalysts without blocking the infrastructure for other measurements.

© RUB, Kramer

„Catalyst syntheses often aim for nanoparticles in order to achieve a high surface area," Wolfgang Schuhmann explains. However, tight and stable fixation of nanopowders on electrodes still remains challenging. Suitable catalyst binders exist for electrodes employed in acidic media. Such binders are often deployed in alkaline environments because of the lack of suitable alternatives. However, a major drawback of using these binder materials in alkaline electrolytes is that they are intrinsically unstable and electrically insulating, thus essentially impeding the application of many highly active and potentially industrially interesting powder catalysts.

Polymer transfoms into carbon

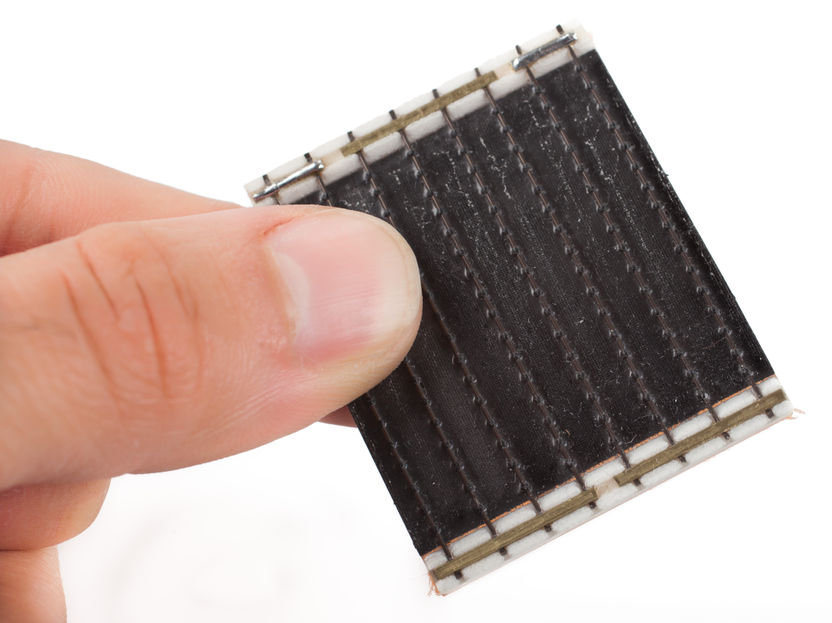

The team from Bochum proposes a new method for tight powder catalyst fixation on metal surfaces. They utilized a specific organic polymer, namely polybenzoxazine, which transforms to carbon at temperatures around 500 degree Celsius. The polymer was applied together with the powder catalyst on the surface of a nickel electrode and subsequently heated at high temperatures. Upon thermal treatment, the polymer transformed into a carbon matrix embedding the powder catalyst particles.

The distinctiveness was the choice of the used polymer. Polybenzoxazines are highly thermal stable and exhibit near-zero shrinkage at higher temperatures. In the absence of oxygen, they carbonize giving high residual char.

Easy to produce

„We expect that the presented method might also be applicable at an industrial scale, although this is yet to be validated. However, the necessary procedures are already well established," Schuhmann says. In principle, it is the same technique as painting the door of a car. „A mixture of catalyst and polymer could be sprayed on an electrode surface, which is then transferred into an oven," the scientist illustrates. The team at the Center for Electrochemical Sciences already tested this at the laboratory scale.

Original publication

Corina Andronescu, Stefan Barwe, Edgar Ventosa, Justus Masa, Eugeniu Vasile, Bharathi Konkena, Sandra Möller, Wolfgang Schuhmann; "Powder catalyst fixation for post-electrolysis structural characterisation of NiFe layered double hydroxide based oxygen evolution reaction electrocatalysts"; Angewandte Chemie International Edition; 2017

Most read news

Original publication

Corina Andronescu, Stefan Barwe, Edgar Ventosa, Justus Masa, Eugeniu Vasile, Bharathi Konkena, Sandra Möller, Wolfgang Schuhmann; "Powder catalyst fixation for post-electrolysis structural characterisation of NiFe layered double hydroxide based oxygen evolution reaction electrocatalysts"; Angewandte Chemie International Edition; 2017

Topics

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Evonik strengthens its focus on adhesive and sealant solutions - New multi-purpose silicone production facility in Geesthacht, Germany

Intelligent material improves aerodynamics in cars and aircraft - Start-up designs active components and systems based on shape memory alloys

Radical in the Black Box - Chemists Reveal the Business Secret of a Catalyst

New material can ‘capture toxic pollutants from air’ - New material is capable of capturing trace amounts of benzene from the air and crucially use less energy than existing materials to do so

Better trap for greenhouse gases

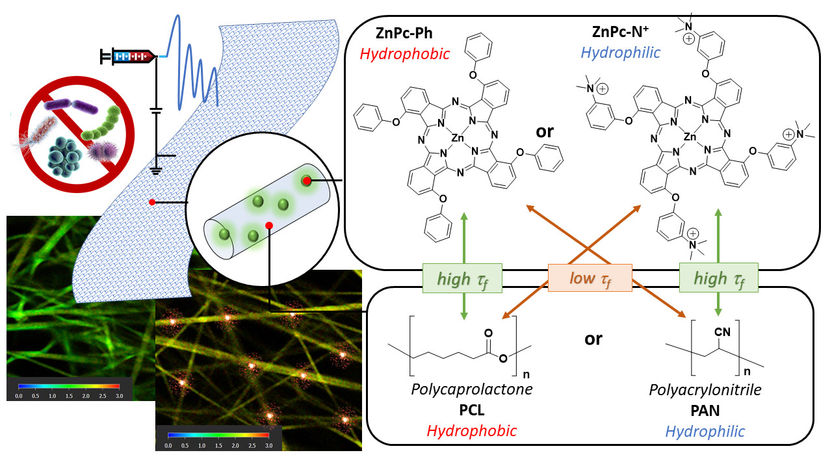

Visualising the Invisible: Active Sites in Antibacterial Nanomaterials - Fluorescence lifetime microscopy has great potential to systematically enhance the effectivenes of antibacterial nanomaterials

R+B Filter GmbH - Langenbrettach, Germany

BRAIN Biotechnology Research And Information Network AG - Zwingenberg, Germany

Evonik exceeds half-year expectations - Outlook increased