New screen coating makes reading in sunlight a lot easier

Screens on even the newest phones and tablets can be hard to read outside in bright sunlight. Inspired by the nanostructures found on moth eyes, researchers have developed a new antireflection film that could keep people from having to run to the shade to look at their mobile devices.

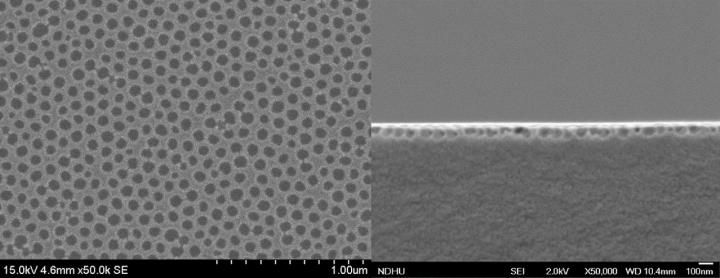

Researchers created a film of moth-eye-like nanostructures that can improve the sunlight visibility of screens on mobile phones and tablets. The images show the nanostructures from above (left) and from the side (right).

Shin-Tson Wu, College of Optics and Photonics, University of Central Florida

The antireflection film exhibits a surface reflection of just .23 percent, much lower than the iPhone's surface reflection of 4.4 percent, for example. Reflection is the major reason it's difficult to read a phone screen in bright sunlight, as the strong light reflecting off the screen's surface washes out the display.

Researchers led by Shin-Tson Wu of the College of Optics and Photonics, University of Central Florida (CREOL), report on their new antireflection coating.

"Using our flexible anti-reflection film on smartphones and tablets will make the screen bright and sharp, even when viewed outside," said Wu. "In addition to exhibiting low reflection, our nature-inspired film is also scratch resistant and self-cleaning, which would protect touch screens from dust and fingerprints."

The new film contains tiny uniform dimples, each about 100 nanometers in diameter (about one one-thousandth of the width of a human hair). The coating can also be used with flexible display applications such as phones with screens that fold like a book, which are expected to hit the market as soon as next year.

Inspired by nature

Many of today's smartphones use a sensor to detect bright ambient light and then boost the screen's brightness level enough to overcome the strong surface reflection. Although this type of adaptive brightness control can help improve readability, it also drains battery power. Other methods for solving the sunlight visibility problem have proved difficult to implement.

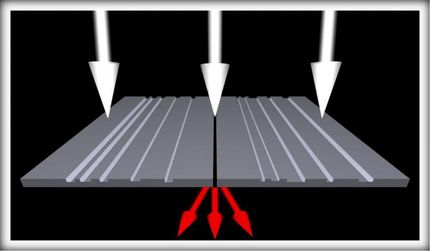

Looking for a simpler approach to improve screen readability outside, the researchers turned to nature. The eyes of moths are covered with a pattern of antireflective nanostructures that allow moths to see in the dark and prevent eye reflections that might be seen by predators. Because other research groups have experimented with using moth-eye-like nanostructures to reduce the sunlight reflected off the surface of solar cells, Wu and his team thought the same technique might also work on mobile screens.

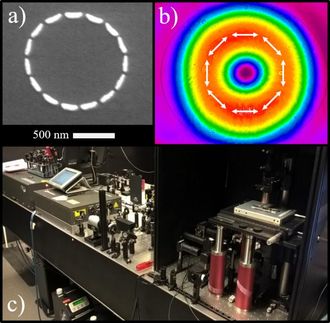

"Although it is known that moth-eye structures can reduce surface reflection, it is relatively difficult to fabricate an antireflection film with this nanostructure that is large enough to use on a mobile phone or tablet," said Guanjan Tan, first author of the paper. "Because the structures are so small, a high-resolution and high-precision fabrication technique is necessary."

The researchers developed a fabrication technique that uses self-assembled nanospheres to form a precise template that can be used to create the moth-eye-like structure on a coating. The simplicity and precision of this process allowed fabrication of the intricate structure in a film large enough to apply to a mobile screen.

The researchers also created a computational model to simulate the optical behavior of the coatings. After showing that the model accurately represented experimental results, the researchers used it to optimize the size of the moth-eye nanostructures to achieve the best performance.

Seeing in the sunlight

Tests of the film after optimization showed that when viewed in sunlight, glass covered with the new film exhibited a more than four-fold improvement in contrast ratio -- the difference between the brightest white and darkest black. When viewed in the shade, glass with the new film showed about a ten-fold improvement in contrast ratio. The researchers also used standard industrial procedures to test its flexibility as well as its anti-scratch and self-cleaning capabilities.

"Our measured results indicate the moth-eye-like antireflection film shows excellent optical behavior and mechanical strength," said Jun-Haw Lee of National Taiwan University, a key member of the research team. "Our film provides an efficient and low-cost method to reduce the surface reflection and improve the sunlight readability of mobile devices."

The researchers are now working to further improve the anti-reflection film's mechanical properties, including finding the best balance of surface hardness and flexibility, to make the film surface rugged enough for long-term use on touch screens. They are also using the simulation model to further optimize the moth-eye structure's shape and size to obtain even better optical performance than ever thought possible.