New catalyst paves way for carbon neutral fuel

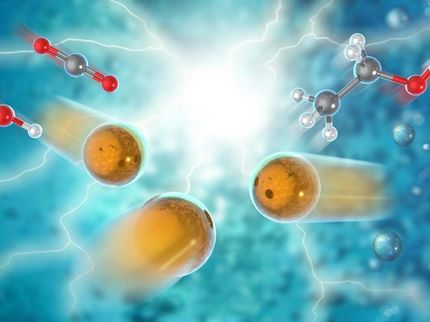

Australian scientists have paved the way for carbon neutral fuel with the development of a new efficient catalyst that converts carbon dioxide (CO2) from the air into synthetic natural gas in a 'clean' process using solar energy.

Undertaken by University of Adelaide in collaboration with CSIRO, the research could make viable a process that has enormous potential to replace fossil fuels and continue to use existing carbon-based fuel technologies without increasing atmospheric CO2.

The catalyst the researchers have developed effectively drives the process of combining CO2 with hydrogen to produce methane (the main component of the fossil fuel natural gas) and water. Currently, natural gas is one of the main fuels used for industrial activities.

"Capturing carbon from the air and utilising it for industrial processes is one strategy for controlling CO2 emissions and reducing the need for fossil fuels," says University of Adelaide PhD candidate Renata Lippi, first author of the research.

"But for this to be economically viable, we need an energy efficient process that utilises CO2 as a carbon source.

"Research has shown that the hydrogen can be produced efficiently with solar energy. But combining the hydrogen with CO2 to produce methane is a safer option than using hydrogen directly as an energy source and allows the use of existing natural gas infrastructure.

"The main sticking point, however, is the catalyst - a compound needed to drive the reaction because CO2 is usually a very inert or unreactive chemical."

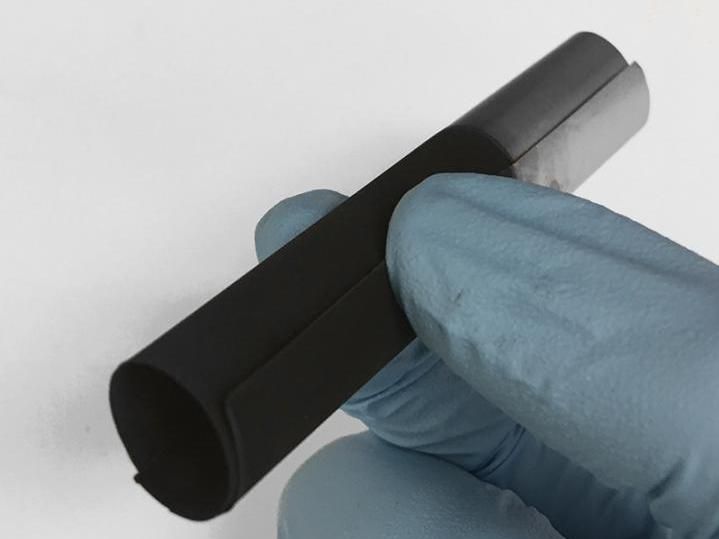

The catalyst was synthesised using porous crystals called metal-organic frameworks which allow precise spatial control of the chemical elements.

"The catalyst discovery process involved the synthesis and screening of more than one hundred materials. With the help of CSIRO's rapid catalyst testing facility we were able to test all of them quickly allowing the discovery to be made in a much shorter period of time," said Dr Danielle Kennedy, AIM Future Science Platform Director with CSIRO. "We hope to continue collaborating with the University of Adelaide to allow renewable energy and hydrogen to be applied to chemical manufacturing by Australian industry."

With other catalysts there have been issues around poor CO2 conversion, unwanted carbon-monoxide production, catalyst stability, low methane production rates and high reaction temperatures.

This new catalyst efficiently produces almost pure methane from CO2. Carbon-monoxide production has been minimised and stability is high under both continuous reaction for several days and after shutdown and exposure to air. Importantly, only a small amount of the catalyst is needed for high production of methane which increases economic viability. The catalyst also operates at mild temperatures and low pressures, making solar thermal energy possible.

"What we've produced is a highly active, highly selective (producing almost pure methane without side products) and stable catalyst that will run on solar energy," says project leader Professor Christian Doonan, Director of the University's Centre for Advanced Nanomaterials. "This makes carbon neutral fuel from CO2 a viable option."

Original publication

Lippi, R. and Howard, S. C. and Barron, H. and Easton, C. D. and Madsen, I. C. and Waddington, L. J. and Vogt, C. and Hill, M. R. and Sumby, C. J. and Doonan, C. J. and Kennedy, D. F.; "Highly active catalyst for CO2 methanation derived from a metal organic framework template"; J. Mater. Chem. A; 2017

Original publication

Lippi, R. and Howard, S. C. and Barron, H. and Easton, C. D. and Madsen, I. C. and Waddington, L. J. and Vogt, C. and Hill, M. R. and Sumby, C. J. and Doonan, C. J. and Kennedy, D. F.; "Highly active catalyst for CO2 methanation derived from a metal organic framework template"; J. Mater. Chem. A; 2017

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Executive Director of FIZ CHEMIE to be General Secretary of IUPAC

Electroplating delivers high-energy, high-power batteries

DKSH opens sales office in Sri Lanka and accomplishes major expansion into the Indian subcontinent