Low cost, scalable water-splitting fuels the future hydrogen economy

The "clean-energy economy" always seems a few steps away but never quite here. Fossil fuels still power transportation, heating and cooling, and manufacturing, but a team of scientists from Penn State and Florida State University have come one step closer to inexpensive, clean hydrogen fuel with a lower cost and industrially scalable catalyst that produces pure hydrogen through a low-energy water-splitting process.

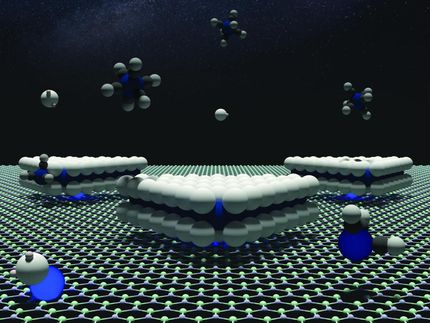

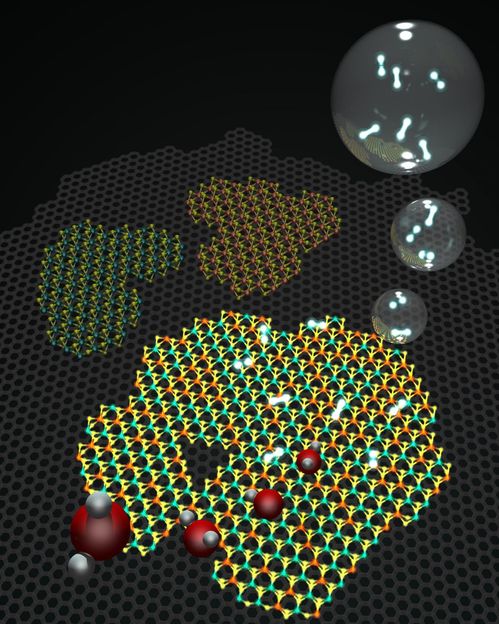

These are molecular models representing a 2-D heterostructure made of graphene (gray background hexagonal lattice), and islands on top of hexagonal WS2 and MoS, as well as an alloy of the two. Water (H2O) molecules in red (oxygen) and gray (hydrogen) come from the bottom left hand side and get transformed catalytically after interacting with the heterostructures into H2 bubbles (top right hand side).

Terrones Group/Penn State

"Energy is the most important issue of our time, and for energy, fuel cells are crucially important, and then for fuel cells, hydrogen is most important," said Yu Lei, Penn State doctoral student describing the water-splitting catalyst she and her colleagues theoretically predicted and then synthesized in the lab. "People have been searching for a good catalyst that can efficiently split water into hydrogen and oxygen. During this process, there will be no side products that are not environmentally friendly."

The current industrial method of producing hydrogen -- steam reforming of methane -- results in the release of carbon dioxide into the atmosphere. Other methods use waste heat, from souces such as advanced nuclear power plants or concentrated solar power, both of which face technical challenges for commercial feasibility. Another industrial process uses platinum as the catalyst to drive the water-splitting process. Although platinum is a near-perfect catalyst, it is also expensive. A cheaper catalyst could make hydrogen a reasonable alternative to fossil fuels in transportation, and power fuel cells for energy storage applications.

"Molybdenum disulfide has been predicted as a possible replacement for platinum, because the Gibbs free energy for hydrogen absorption is close to zero," said Mauricio Terrones, professor of physics, materials science and engineering, and chemistry, Penn State. The lower the Gibbs free energy, the less external energy has to be applied to produce a chemical reaction.

However, experimentally, there are drawbacks to using molybdenum disulfide as a catalyst. In its stable phase, molybdenum disulfide is a semiconductor, which limits its ability to conduct electrons. To get around that problem, the team added reduced graphene oxide, a highly conducting form of carbon. Then, to further decrease the free energy, they alloyed the molybdenum disulfide with tungsten to create a thin film with alternating graphene and tungsten-molybdenum disulfide layers. The addition of tungsten lowers the electrical voltage required to split water by half, from 200 millivolts with pure molybdenum disulfide, to 96 millivolts with the tungsten-molybdenum alloy.

The water splitting process uses a very small amount of electrical energy applied to an electrode immersed in water. Using this small potential, the protons in the solution can be absorbed onto the surface of the catalyst. Then two protons will migrate together to form a hydrogen bubble that rises to the surface and releases the hydrogen.

From the theoretical point of view, the electron orbitals play a crucial role. In the case of pure molybdenum disulfide, the electron orbitals from the metal do not overlap well with the electron orbital of hydrogen in the key reaction step. However, when the alloy is present these orbitals interact well and make the reaction more efficient. This is similar to what platinum does, and the reason why platinum is so energy efficient when used in this chemical reaction. However, in this work, researchers showed that cheaper and more abundant elements can be used and reach an efficiency that outperforms all the best catalysts.

"What happens in these alloys is an exquisite overlap of orbitals which makes the reaction more efficient," said Jose L. Mendoza-Cortes, professor of chemical engineering, materials science and engineering and scientific computing at Florida State. "This is not observed in the pure components. It is an example where the hybrid is better than the pure components."

Hydrogen fuel cells can boost a clean-energy economy not only in the transportation sector, where fast fueling and vehicle range outpace battery-powered vehicles, but also to store electrical energy produced by solar and wind. This research is another step forward to reaching that goal.