MOFs provide a better way to remove water from gas

The conventional view that metal-organic frameworks (MOFs) cannot be stable in water has been overturned by the development of an MOF that can selectively and effectively adsorb water to dry gas streams.

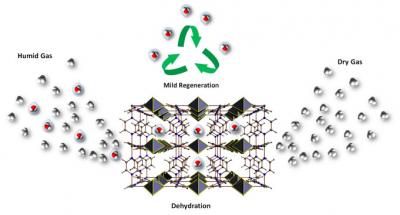

This image shows energy efficient gas drying achieved by a metal-organic framework.

© 2017 Mohamed Eddaoudi

"The achievement of energy efficient dehydration by our MOF is revolutionary," said Professor Mohamed Eddaoudi, Director of the Advanced Membranes and Porous Materials (AMPM) at the KAUST Division of Physical Science and Engineering.

Gases, such as natural gas, must be dehydrated before transportation and use to avoid problems including pipeline corrosion and blockages due to methane ice formation. Conventional drying agents require an energy-intensive regeneration cycle.

The new fluorinated MOF developed by the KAUST team achieves the drying and regeneration cycle at relatively low temperatures and requires about half the energy input of conventional procedures. This dramatic reduction in energy use highlights the obvious potential for upscaling the innovation to bring huge efficiency savings in the gas production and transport industry.

MOFs are hybrid organic-inorganic materials that contain metal ions or clusters held in place by organic molecules known as linkers. Varying the metal components and organic linkers allows researchers to fine-tune the structure and chemical properties of MOFs. A major aim of this fine-tuning is to create MOFs with cavities that will selectively bind to and retain specific molecules, such as the water that must be removed from a gas stream.

"Initially, our aim was to adapt our recently introduced fluorine-containing MOFs, to include a periodic array of open metal sites and fluorine centers in the contracted pore system, to achieve various key separations," said Eddaoudi. This exploration led to the discovery of a water-stable MOF-- now labeled KAUST-8-- with unique water adsorption properties and outstanding recyclable dehydration capabilities. Significantly, KAUST-8 removes carbon dioxide along with water, which is a common requirement in industrial gas processing.

"I have no doubt that this discovery will inspire scientists in academia and industry to explore MOFs to address other challenges," said Eddaoudi. The KAUST team sees additional possibilities may include the removal of water from liquids, such as inks and solvents used in the electronics industry.

Original publication

Cadiau, Amandine and Belmabkhout, Youssef and Adil, Karim and Bhatt, Prashant M. and Pillai, Renjith S. and Shkurenko, Aleksander and Martineau-Corcos, Charlotte and Maurin, Guillaume and Eddaoudi, Mohamed; "Hydrolytically stable fluorinated metal-organic frameworks for energy-efficient dehydration"; Science; 2017

Most read news

Original publication

Cadiau, Amandine and Belmabkhout, Youssef and Adil, Karim and Bhatt, Prashant M. and Pillai, Renjith S. and Shkurenko, Aleksander and Martineau-Corcos, Charlotte and Maurin, Guillaume and Eddaoudi, Mohamed; "Hydrolytically stable fluorinated metal-organic frameworks for energy-efficient dehydration"; Science; 2017

Topics

Organizations

Other news from the department science

These products might interest you

Anopore™ by Cytiva

Precise filtration made easy with Anopore inorganic membranes

The aluminum oxide filter membrane that can increase the purity or yield of your analyte

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.