Coatings for nuclear fuel preventing explosions in reactors

Protective titanium nitride-based coatings will be a barrier protecting zirconium fuel rods

Advertisement

Physicists from Tomsk Polytechnic University are creating protective titanium nitride-based coatings for shells of fuel elements (fuel rods) of nuclear reactors. Such shells can significantly reduce hydrogenation of containers in which nuclear fuel is placed, extend their service life and protect reactor from explosion like at the Fukusima radiation disaster.

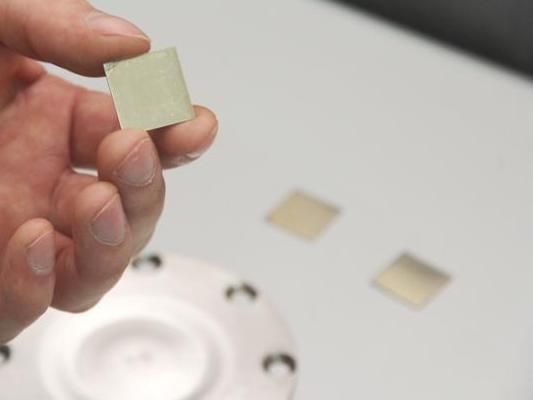

A thin film coating is no more than two microns thick.

Tomsk Polytechnic University

"In reactors nuclear fuel is laid in special "tubes" out of zirconium alloys, to form fuel rods. In the fuel rods, a nuclear reaction takes place. As a result of radiolysis of a reactor coolant - water, and also as a result of interaction of the coolant and zirconium under high temperatures hydrogen is released. Hydrogen is able to accumulate in fuel rods shells causing degradation of their mechanical properties and destruction," clarifies one of the developers, an assistant at the Department of General Physics Egor Kashkarov.

According to the young scientist, the danger of interaction of zirconium and water is the higher temperature in the reactor is, the more hydrogen is released. For example, the same happened at the Fukusima-1 station in Japan: due to flooding of pumping equipment the active zone of the reactor warmed up to more than 1,200 °C, a steam-zirconium reaction proceeded swiftly and a large amount of hydrogen was released. The explosion of accumulated hydrogen was one of the biggest radiation accidents in the world.

The scientific team from the TPU Department of General Physics is creating protective titanium nitride-based coatings that will be a barrier protecting zirconium fuel rods from water and hydrogen accumulation.

"During tests titanium nitride has proved itself well: it has high hardness, wear resistance, heat resistance and inertia. We also found that it protects well from hydrogen penetration into the material, what is critical for nuclear energy. The coatings can reduce hydrogen penetration in zirconium alloy," adds Egor Kashkarov.

The coatings on zirconium substrate are applied using two technologies: magnetron sputtering and vacuum arc deposition. The both processes are carried out on a set-up created in the university. The result is a thin film coating - no more than two microns thick.

"One of the applications of the elaborating coatings out of titanium nitride is next generation reactors and thermal nuclear reactors where hydrogen impermeable coating is a pressing issue. In the next generation reactors, temperature is supposed to increase up to 400-450 °C to improve fuel burn-up efficiency. Consequently, hydrogenation of fuel rods will be here much faster. Our coatings are able to prevent it," says the developer.