Improved corrosion protection with flake-type zinc-phosphate particles

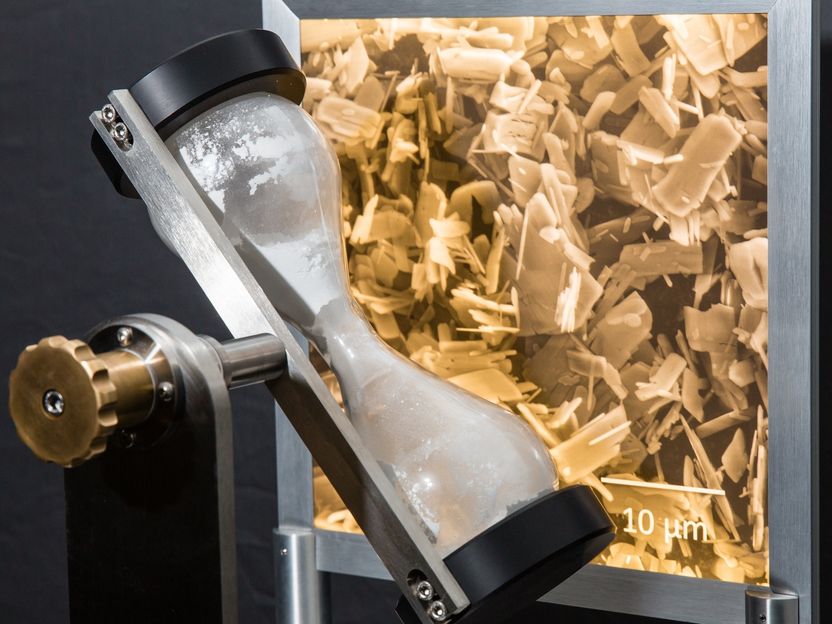

Large quantities of steel are used in architecture, bridge construction and ship-building. Structures of this type are intended to be long-lasting. Furthermore, even in the course of many years, they should not lose any of their qualities regarding strength and safety. For this reason, the steel plates and girders used must have extensive and durable protection against corrosion. In particular, the steel is attacked by oxygen in the air, water vapor and salts. To prevent the corrosive substances from penetrating into the material, a common method is to create an anti-corrosion coating by applying paint layers of zinc-phosphate particles. Now, research scientists at INM – Leibniz Institute for New Materials developed a special type of zinc-phosphate particles: They are flake-like in shape because they are ten times as long as they are thick.

Because of the disordered arrangement of the flakes, they can not run through the sandglass like spheric particles do

Ollmann

First experiments with those new, flake-type shaped particles indicate, because of their anisotropy, a better solubility compared to spherical particles. “Now, more phosphate-ions are soluted and repassivation of bare metal surface, for example as a consequence of a mechanical damage, is better and faster,” the head of the program division Nanomers®, Carsten Becker-Willinger says.

“In first test coatings, we were also able to demonstrate that the flake-type particles are deposited in layers on top of each other thus creating a wall-like structure. This means that the penetration of gas molecules through the protective coating is longer because they have to find their way through the ´cracks in the wall´,” the chemist Becker-Willinger explains. The result was, that the corrosion process was much slower than with coatings with spheroidal particles where the gas molecules can find their way through the protective coating to the metal much more quickly.

In further series of tests, the scientists were able to validate the effectiveness of the new particles. To do so, they immersed steel plates both in electrolyte solutions with spheroidal zinc-phosphate particles and with flake-type zinc-phosphate particles in each case. After just a few hours, the steel plates in the electrolytes with spheroidal particles were showing signs of corrosion whereas the steel plates in the electrolytes with flake-type particles were still in perfect condition, even after three days.

The flake-type shaped zinc-phosphate particles are synthesized in a controlled precipitation process developed at INM.

The developers will be demonstrating their results and the possibilities they offer at stand B46 in hall 2 at this year's Hannover Messe which takes place from 24th to 28th April.

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.