Microprocessors based on a layer of just three atoms

Two-dimensional materials, or 2D materials for short, are extremely versatile, although - or often more precisely because - they are made up of just one or a few layers of atoms. Graphene is the best-known 2D material. Molybdenum disulphide (a layer consisting of molybdenum and sulphur atoms that is three-atoms thick) also falls in this category, although, unlike graphene, it has semiconductor properties. With his team, Dr Thomas Mueller from the Photonics Institute at TU Wien is conducting research into 2D materials, viewing them as a promising alternative for the future production of microprocessors and other integrated circuits.

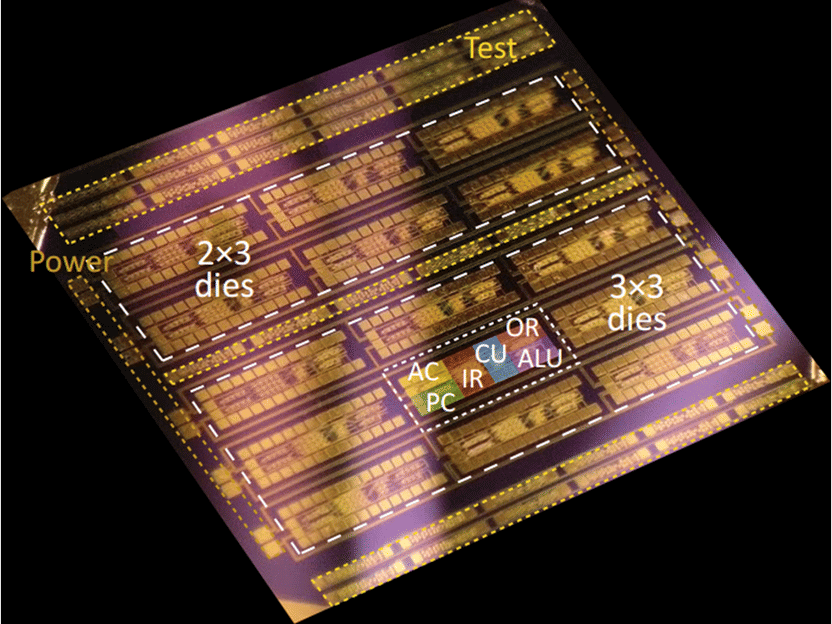

Overview of the entire chip. AC = Accumulator, internal buffer; PC = Program Counter, points at the next instruction to be executed; IR = Instruction Register, used to buffer data- and instruction-bits received from the external memory; CU = Control Unit, orchestrates the other units according to the instruction to be executed; OR = Output Register, memory used to buffer output-data; ALU = Arithmetic Logic Unit, does the actual calculations.

Copyright: Stefan Wachter

The whole and the sum of its parts

Microprocessors are an indispensable and ubiquitous component in the modern world. Without their continued development, many of the things we take for granted these days, such as computers, mobile phones and the internet, would not be possible at all. However, while silicon has always been used in the production of microprocessors, it is now slowly but surely approaching its physical limits. 2D materials, including molybdenum disulphide, are showing promise as potential replacements. Although research into individual transistors - the most basic components of every digital circuit - made of 2D materials has been under way since graphene was first discovered back in 2004, success in creating more complex structures has been very limited. To date, it has only been possible to produce individual digital components using a few transistors. In order to achieve a microprocessor that operates independently, however, much more complex circuits are required which, in addition also need to interact flawlessly.

Thomas Mueller and his team have now managed to achieve this for the first time. The result is a 1-bit microprocessor consisting of 115 transistors over a surface area of around 0.6 mm2 that can run simple programs. "Although, this does of course seem modest when compared to the industry standards based on silicon, this is still a major breakthrough within this field of research. Now that we have a proof of concept, in principle there is no reason that further developments can't be made," says Stefan Wachter, a doctoral student in Dr Mueller's research group. However, it was not just the choice of material that resulted in the success of the research project. "We also gave careful consideration to the dimensions of the individual transistors," explains Mueller. "The exact relationships between the transistor geometries within a basic circuit component are a critical factor in being able to create and cascade more complex units."

Future prospects

It goes without saying that much more powerful and complex circuits with thousands or even millions of transistors will be required for this technology to have a practical application. Reproducibility continues to be one of the biggest challenges currently being faced within this field of research along with the yield in the production of the transistors used. After all, both the production of 2D materials in the first place as well as the methods for processing them further are still at the very early stages. "As our circuits were made more or less by hand in the lab, such complex designs are of course pretty much beyond our capability. Every single one of the transistors has to function as planned in order for the processor to work as a whole," explains Mueller, stressing the huge demands placed on state-of-the-art electronics. However, the researchers are convinced that industrial methods could open up new fields of application for this technology over the next few years. One such example might be flexible electronics, which are required for medical sensors and flexible displays. In this case, 2D materials are much more suitable than the silicon traditionally used owing to their significantly greater mechanical flexibility.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.