New sustainability in the tanning process

Resource-efficient manufacturing of leather chemicals

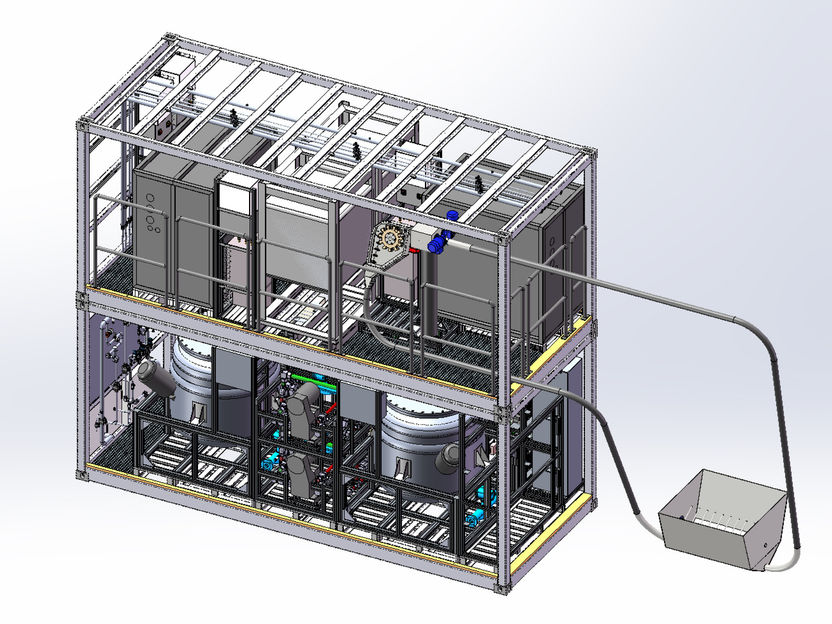

Specialty chemicals company LANXESS is leading a research and development project to investigate an innovative technology for a new recycling concept in leather manufacturing. Under the title “Resource-efficient manufacturing of leather chemicals” (ReeL), LANXESS Leather business unit is working with the Leverkusen-based research institute INVITE to develop a modular pilot plant that can use shavings previously disposed in most cases and organic biomass to create “X-Biomer” brand retanning agents for manufacturing leather. The manufacturing equipment is designed for use directly on-site at the tanneries. The feasibility tests are set to take place with the third project partner, HELLER-LEDER GmbH Co. KG tannery in Hehlen, Lower Saxony.

Modular pilot plant that can use shavings and waste cuts previously disposed of in most cases and organic biomass to create “X-Biomer” brand retanning agents for manufacturing leather. The plant is designed for use directly on-site at tanneries.

INVITE GmbH

“As one of the largest manufacturers of chemicals for the leather industry, we consider the sustainability of these processes to of particular importance to us,” says Luis López-Remón, head of the Leather business unit at LANXESS. “Our goal with this project is to highlight how production waste during leather manufacture can be recycled directly in the tannery, thus significantly improving the sustainability profile compared to the conventional production of retanning agents in centralized production facilities located far away from the tanneries.”

In this way, a tannery would be able to automatically and largely independently manufacture enough retanning agents, such as the X-Biomer range offered by LANXESS, to meet part of its own needs. “I feel this approach is an extremely promising step toward an even more sustainable production concept,” says Dr. Dietrich Tegtmeyer, head of the project at LANXESS. “First of all, ‘in situ’ and ‘just in time’ production save an enormous amount of logistics and packaging resources and on top of that there is no need to dispose the production waste as it can serve as raw material for the retanning chemicals required.”

The joint project has a total investment volume of around five million euros and was launched in January 2016. Almost half of this investment is provided by a grant from the German Federal Ministry of Education and Research (BMBF) which runs for three years. LANXESS is currently working on adapting and optimizing procedures in its Leverkusen laboratory to perfect the chemical recycling process. The INVITE research institute is primarily responsible for planning and constructing the pilot plant. To test the innovative production concept under real conditions, one of these plants will be completed in April 2017, and after some cold commissioning tests to check the process control technology, it will go into feasibility operations at HELLER-LEDER in mid-2017.

So far, the modular plant concepts designed by INVITE were primarly developed to achieve technological process improvements and flexible, continuous production processes. In this project the benefits of the concept’s application as decentralized production concept for a mature industry come to the fore for the first time. “For us, this project idea is an important step toward opening up a broader application spectrum,” says Armin Schweiger, Managing Director of INVITE. “We also see the ReeL project as a significant boost to technology.”

Complete recycling without emissions

A medium-sized tannery produces between one and two metric tons of shavings a day. Using a production plant, e.g. leased from LANXESS, the company could manufacture a comparable volume of liquid X-Biomer directly on site. Every trace of the waste is recycled, leaving no residue, and without generating any emissions.

Tegtmeyer: “The goal of the project is to be able to offer X-Biomer to the tanner at a similar cost to the procurement of conventional retanning agents. The lack of logistics outlay should, for example, offset the higher production costs for the design. Piloting is being carried out to verify this concept model. In addition, the project will most certainly benefit sustainability.”

The project is receiving funding from the German Federal Ministry of Education and Research as part of its “r+Impuls – Innovative Technologien für Ressourceneffizienz – Impulse für industrielle Ressourceneffizienz” (r+Impulse – innovative technologies for resource efficiency – impetus for industrial resource efficiency). This program supports projects that are bringing innovative technologies and products out of the laboratory and into commercial use.