New application of the selective laser melting method

Advertisement

Scientists of Peter the Great St. Petersburg Polytechnic University (SPbPU) and Delft University of Technology developed a technology for obtaining new metal structures by selective laser melting method (additive technology of manufacturing three-dimensional objects from metal powders).

Researchers of Peter the Great St. Petersburg Polytechnic University and Delft University of Technology obtained a gradient microstructure of the material and created a product, combining properties of two metals.

Peter the Great St. Petersburg Polytechnic University

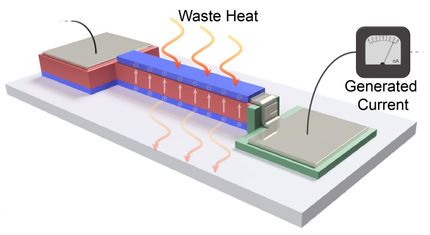

Due to this technology it is possible to obtain a gradient microstructure of the material and create a product, combining the properties of two metals. This material is characterized by high performance characteristics, such as temperature and pressure effects, strength, durability.

"This technology can be used for manufacturing of products operating in extreme conditions, such as high pressure and temperature," says Vadim Sufiiarov, assistant professor of "Development, technologies and materials in aircraft engine building" department of the Institute of Metallurgy, Mechanical Engineering and Transport SPbPU.

"Therefore, this development can be applied for manufacturing of gas turbines elements for aviation, energy and marine," adds Sufiiarov.

Generally, selective laser melting may be used to produce a fine-grained microstructure of the metal, which provides high mechanical properties at room temperature. However, the gases at combustion chamber exit of the gas turbine engine have the highest temperature and pressure. The gases aggressively act on the elements of the hot part of the turbine, primarily on blades and vanes, which are responsible for the rotor mechanism.

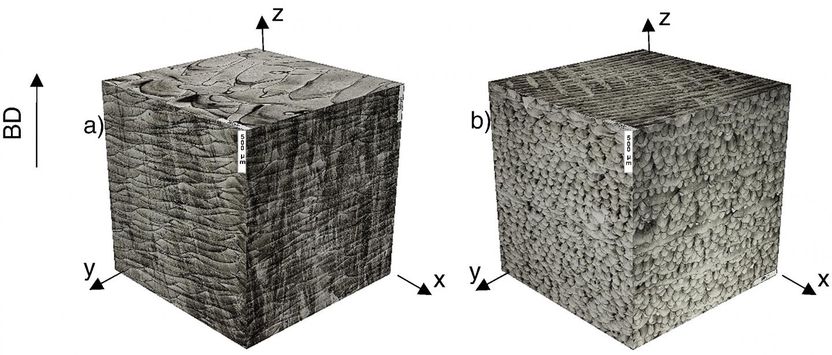

The first and second stage blades have the highest load, so they are not simply made using specially designed high-temperature alloys, but also form a special microstructure in the product. It is either single-crystal (when the product consists of one crystal and one grain type) or directionally crystallized (no grain boundaries in the transverse direction, all grain boundaries are located only along longitudinal direction).

With the help of this technology it is possible to create both equiaxial structures, where the grains have approximately the same dimensions in all directions, as well as directionally crystallized grains and combine their arrangement in one product. Developed approach of additive technologies allows flexible control of material microstructure formation.