Nano-level lubricant tuning improves material for electronic devices and surface coatings

molybdenum disulfide (MoS2), which is ubiquitously used as a solid lubricant, has recently been shown to have a two-dimensional (2D) form that is similar to graphene. But, when thinned down to less than a nanometer thick, MoS2 demonstrates properties with great promise as a functional material for electronic devices and surface coatings.

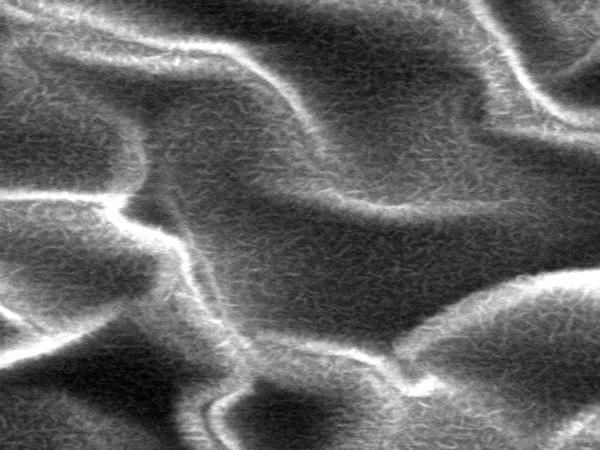

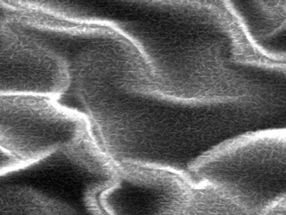

This is a scanning electron microscope image of atomically-thin MoS2 with hierarchical, dual-scale structures.

SungWoo Nam, University of Illinois

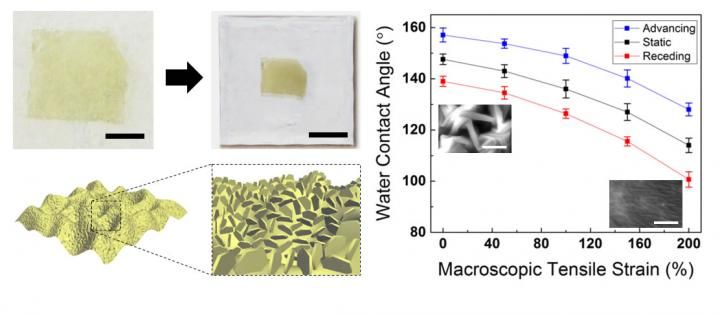

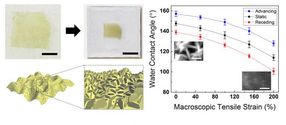

Image shows how controlled and dynamic surface architecturing/roughening of atomically thin MoS2 affects wettability.

SungWoo Nam, University of Illinois

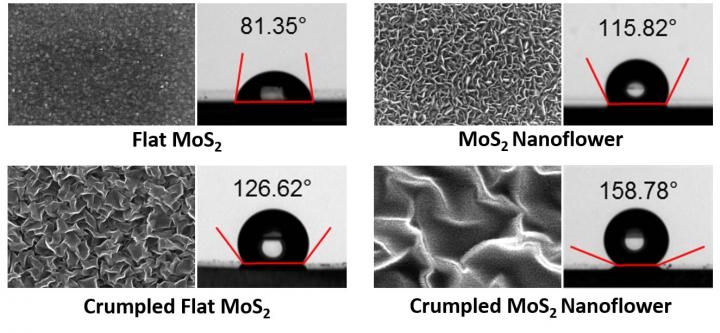

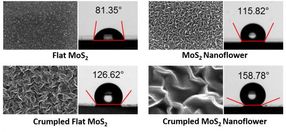

Images of atomically thin MoS2 with micro- and nano-scale roughnesses and their corresponding water contact angles.

SungWoo Nam, University of Illinois

Researchers at the University of Illinois at Urbana-Champaign have developed a new approach to dynamically tune the micro- and nano-scale roughness of atomically thin MoS2, and consequently the appropriate degree of hydrophobicity for various potential MoS2-based applications.

"The knowledge of how new materials interact with water is a fundamental," explained SungWoo Nam, an assistant professor of mechanical science and engineering at Illinois. "Whereas the wettability of its more famous cousin, graphene, has been substantially investigated, that of atomically thin MoS2--in particular atomically thin MoS2 with micro- and nano-scale roughness--has remained relatively unexplored despite its strong potential for fundamental research and device applications. Notably, systematic study of how hierarchical microscale and nanoscale roughness of MoS2 influence its wettability has been lacking in the scientific community."

"This work will provide a new approach to dynamically tune the micro- and nano-scale roughness of atomically thin MoS2 and consequently the appropriate degree of hydrophobicity for various potential MoS2-based applications," stated Jonghyun Choi, a mechanical engineering graduate student and first author of the article. "These include waterproof electronic devices with superhydrophobicity with water contact angle greater than 150 degrees. It may also be useful for medical applications with reduced hydrophobicity (WCA less than 100 degrees) for effective contact with biological substances. "

According to the authors, this study, expands the toolkit to allow tunable wettability of 2D materials, many of which are just beginning to be discovered.

"When deformed and patterned to produce micro- and nano-scale structures, MoS2 shows promise as a functional material for hydrogen evolution catalysis systems, electrodes for alkali metal-ion batteries, and field-emission arrays," Nam added. "The results should also contribute to future MoS2-based applications, such as tunable wettability coatings for desalination and hydrogen evolution."

Original publication

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.