Axalta invests to expand its powder coatings production capacity in Germany

Axalta coating systems has invested to expand and to optimize manufacturing capabilities at its powder coatings production facilities in Landshut, Germany due to growing market demand.

The investment supports Axalta’s powder coatings growth strategy and follows progress in its powder coating business in Eastern Europe coupled with increased demand from Central Europe. It is the second investment to expand powder production in the Europe, Middle East and Africa (EMEA) region this year. The first was at Axalta’s Montbrison, France, facility in April 2016, which saw lean automation and upgraded production technology appreciably increase line capacity and productivity.

“Minimal supply time is very important to our customers, and that’s one of the reasons we chose to invest in the Landshut site. Once complete, the additional production facilities will provide significantly greater capacity. This means we will produce even more of our high quality powder coatings for the Austrian, German, Italian and Swiss markets, as well as those in Eastern Europe,” says Matthias Schönberg, Vice President of Axalta Coating Systems and President of its EMEA region.

Axalta’s powder coatings offer outstanding mechanical properties, are highly resistant to weathering and are well-suited for architectural façade applications.

The investments in Montbrison and in Landshut demonstrate Axalta’s commitment over the past two years to further develop capacity and increase productivity in the manufacture of its coatings around the world in order to meet its customers’ needs. The expansion project in Landshut consists of three phases, and is due to be completed by the end of March 2017. Phases one and two concluded at the end of 2015 and in March 2016 respectively.

Most read news

Organizations

Other news from the department business & finance

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Nanosilver has no place in food, textiles or cosmetics - BfR currently advises against using nanoscale silver ions in consumer products

Linde to build industrial-scale air separation units for steel manufacturer TISCO in China

Chr. Hansen, S.A. - Tres Cantos, Spain

Rosneft and BP Form Global and Arctic Strategic Alliance

Bayer Technology Services to supply chlorine drying unit to China

AkzoNobel strongly supports Chairman of the Supervisory Board - AkzoNobel calls on Elliott Advisors and PPG to clarify relationship

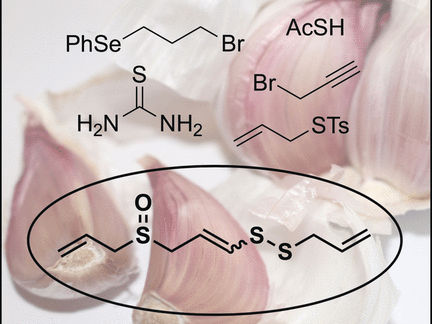

Garlic ingredient from the lab bench - Total synthesis of ajoene, a biologically active component in oil extracts of garlic

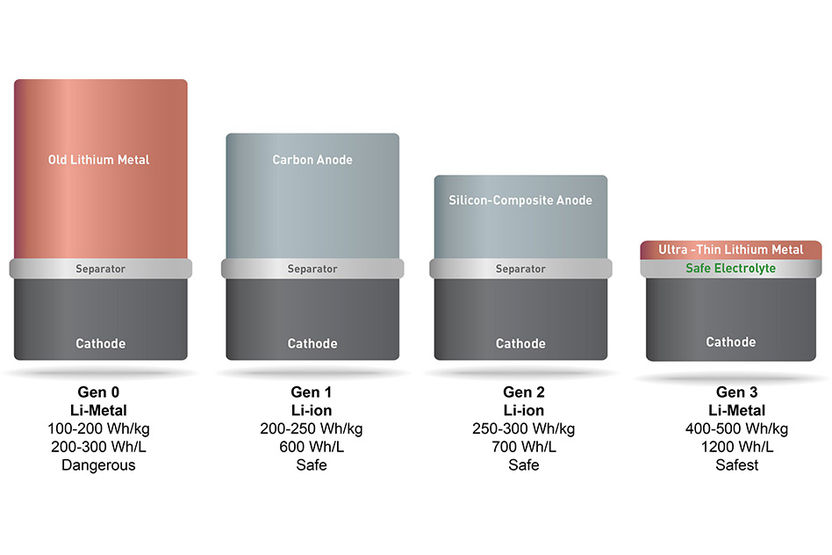

Doubling battery power of consumer electronics - New lithium metal batteries could make smartphones, drones, and electric cars last twice as long.

Flow Chemistry Scale Up for Microwave Reactions