Biochemistry: Combining two catalytic worlds

This is how chemical processes could become more environmentally friendly

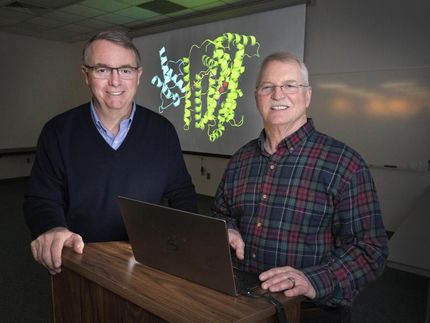

Chemical and biological catalysts tend to require very different reaction conditions, making their combination challenging. Researchers of the Ruhr-Universität Bochum have succeeded in taking this hurdle by using a special gel matrix to compartmentalize both types of catalysts. The results obtained by the Junior Research Group for Microbial Biotechnology headed by Prof Dr Robert Kourist have been reported in the journal Angewandte Chemie.

More biology for the chemical industry – that is their aim: Dennis Reichert, Robert Kourist and Álvaro Gómez Baraibar (from left to right)

© RUB, Kramer

Benefits of enzyme catalysts

"Enzymes are environmentally friendly biological catalysts which are now in the focus of modern synthetic chemistry," says Robert Kourist. The reason: they operate under mild reaction conditions such as neutral pH and low temperatures. Also, they are very selective and manufacture only the desired product while reducing the amount of by-products.

However, there are a number of reactions, for which no suitable enzymes have been found so far. These reactions have to be performed by chemical catalysts. "A combination of the classic chemical catalysts and enzymes is a step towards more environmentally friendly chemical processes," says Kourist. "A challenge is to use them in the same reaction due to their different requirements concerning reaction conditions."

Different reaction spaces

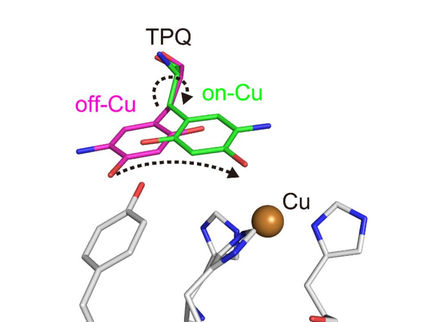

Chemical catalysts are often organo-metallic compounds that require an organic solvent as the reaction media. However, there are only a few enzymes that can remain active in such an environment.

The Bochum-based scientists Dr Álvaro Gómez Baraibar and PhD candidate Dennis Reichert managed to encapsulate an enzyme in a special gel matrix which allowed its use in pure organic solvents. Using this strategy, they achieved the sequential combination of an enzymatic step and a chemical reaction.

Reaction cascade saves time and cost

"The combination of the individual reaction steps in a cascade has more advantages," says Reichert. It is not necessary to purify the product after each intermediate step because it can be used in the reaction directly as a raw material for the next step. This saves time and costs," he explains.

The team demonstrated this new approach with the synthesis of polyphenols. "These natural substances are used predominantly as natural antioxidants," Kourist says. "They are also at the heart of different studies as new drugs used in cancer therapies."

Synthetic manufacture of polyphenols is expensive, and the yield is low. The Bochum-based group showed that the cascade reaction can be performed successfully by the application of a gel matrix.

Original publication

Original publication

Álvaro Gómez Baraibar, Dennis Reichert, Carolin Mügge, Svenja Seger, Harald Gröger, Robert Kourist; "A sequential one-pot cascade reaction combining an encap-sulated decarboxylase with metathesis for the synthesis of bio-based antioxidants"; Angewandte Chemie International Edition; 2016

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.