First-ever 3D printed excavator project advances large-scale additive manufacturing R&D

Heavy construction machinery is the focus of Oak Ridge National Laboratory’s latest advance in additive manufacturing research. With industry partners and university students, ORNL researchers are designing and producing the world’s first 3D printed excavator, a prototype that will leverage large-scale AM technologies and explore the feasibility of printing with metal alloys.

The first-ever 3D printed excavator will include a cab designed by a University of Illinois at Urbana-Champaign student engineering team and printed at DOE’s Manufacturing Demonstration Facility at ORNL using carbon fiber-reinforced ABS plastic.

Oak Ridge National Laboratory

Increasing the size and speed of metal-based 3D printing techniques, using low-cost alloys like steel and aluminum, could create new industrial applications for additive manufacturing.

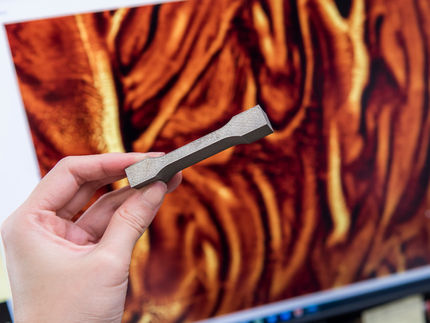

The excavator will be 3D printed using machines at the Department of Energy’s Manufacturing Demonstration Facility at ORNL to create and assemble three components: the cab where the operator sits, the stick (a large hydraulically articulated arm) and a heat exchanger. The excavator’s stick will be fabricated using the newly installed Wolf System, a machine that uses a freeform technique in printing large-scale metal components. The heat exchanger will be printed on a Concept Laser machine that produces metal parts through a powder-bed-based laser melting process.

When 3D printing the excavator’s stick and heat exchanger, the team will further develop processes to improve material performance and printability and also validate models that will show how they can adapt to reduce residual stress and distortion.

“The beauty of a project of this size and scope is that it brings together many intelligent people to work on a number of challenges while accomplishing a common goal,” said Lonnie Love, who’s leading the 3D printed excavator project with ORNL’s Manufacturing Systems Research group. He expects the excavator to be printed, assembled and ready to be unveiled in only nine months.

3D printing an excavator for the first time is a learning experience for both seasoned researchers and the next generation of engineers.

A student engineering team from the University of Illinois at Urbana-Champaign won a design competition and recently visited the MDF to watch their cab design take shape on the Big Area Additive Manufacturing machine – the same system co-developed by ORNL and Cincinnati Incorporated that produced a replica Shelby Cobra sports car using carbon fiber-reinforced acrylonitrile butadiene styrene, or ABS, plastic.

“While hundreds of people, many of whom are students, visit the MDF each year, this is the first student group to watch their design 3D printed on one of our large-scale machines,” Love said. Additionally, Georgia Institute of Technology student Clayton Greer worked on the excavator’s stick as an ORNL intern.

“We’re also exposing them to the possibilities that additive manufacturing is affording industry that can help companies from so many different areas whether it’s automotive, construction or other applications yet to be discovered,” he added.

The completed excavator project, known as Project AME (Additive Manufactured Excavator), will be on display at IFPE and CONEXPO-CON/AGG in Las Vegas. Plans are in the works to 3D print another excavator cab during a live demonstration at the event.

While 3D printing excavators, or any other construction vehicles, may not become common practice among manufacturers, Love said using AM to print low-volume, high-complexity components could benefit the construction industry by reducing production time and overall cost.

“Additive manufacturing can be used to print components on demand, which could potentially eliminate the need for mass storage, organization and transportation,” Love said.

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.