Covestro expands position in coating raw materials

Capacity at site increased by about 50,000 metric tons per year

With demand for high performance coatings and adhesives growing in Asia, materials manufacturer Covestro is expanding production of the crucial raw material HDI. To satisfy this demand, a new world-scale plant at the Shanghai site in China has been inaugurated. It can produce up to 50,000 metric tons of HDI per year. The production technology is highly environmentally friendly, efficient and safe. The plant represents another milestone in an expiring major investment program for the site.

“Particularly in China and the Asia-Pacific region, there is strong demand for coatings and adhesives in such key sectors as the automotive, construction and furniture, footwear and textiles industries. We believe there is considerable potential for growth through product and application innovations, and we are responding to that with the expansion of our HDI production capacity,” said Daniel Meyer, head of the Coatings, Adhesives, Specialties (CAS) segment at Covestro, on Thursday at the inauguration celebration. Focusing particularly on the needs of customers in the region, Meyer added that the new plant will help ensure a stable and flexible supply of HDI.

Covestro’s new HDI plant at Shanghai, China can produce up to 50,000 metric tons of the coatings raw material per year and is very environmentally friendly, efficient and safe.

Covestro

Basis for innovative products and solutions

At the same time, the material forms the basis for many innovative products and solutions. Meyer added, “Covestro used it in the development of BLULOGIQ, for example, a unique technology for coating plastic automotive parts that is highly energy efficient and delivers significant cost savings.” With this and other innovations, Covestro is helping to meet global challenges such as the ongoing depletion of resources and environmental pollution – entirely in keeping with the company’s purpose: “To make the world a brighter place.”

Dr. Klaus Schäfer, the Covestro Management Board member responsible for production and technology, said, the addition of the new plant makes Shanghai one of the largest HDI production centers in the world. “At this important site we work in a network to produce all our main products. Now it is stronger than ever before thanks to the expansion of our HDI production,” he added.

The new plant is part of an investment program for the site with a volume of more than EUR 3 billion which was launched over ten years ago and is now expiring.This program also calls for polycarbonate production capacities at the site to double to about 400,000 metric tons per year before the end of in 2016. This versatile, high-performance plastic is used in a number of industries, including the automotive, construction and electronics sectors.

State of the art

“The new plant features the very latest technology,” Schäfer added. “It’s not only very safe and highly efficient; it also stands out because of its particularly environmentally friendly production process.” In the last process step, for example, the use of solvents has been cut by up to 80 percent and up to 60 percent less energy is used compared with the conventional technology. Overall, the carbon footprint of HDI production has been reduced by up to 70 percent.

Other news from the department business & finance

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Analytik Jena AG more than doubles revenue in first nine months of fiscal year

Sambucus_canadensis

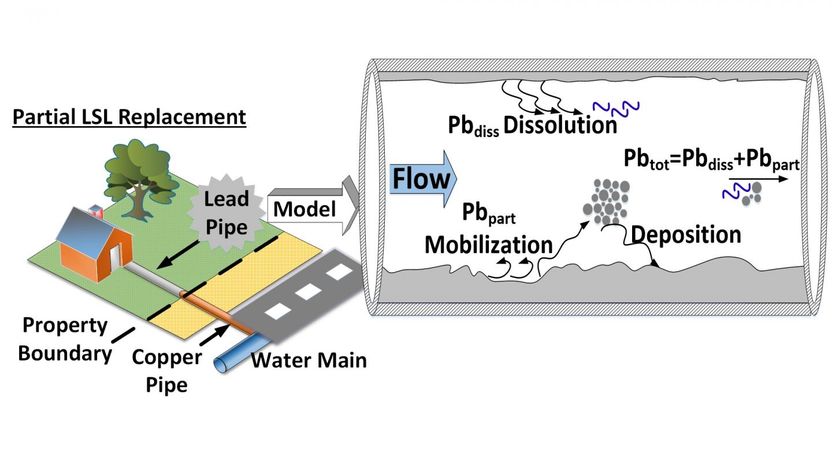

Preventing lead spread