Tiniest imperfections make big impacts in nano-patterned materials

A research team at Clarkson University reports an interesting conclusion that could have major impacts on the future of nano-manufacturing. Their analysis for a model of the process of random sequential adsorption (RSA) shows that even a small imprecision in the position of the lattice landing sites can dramatically affect the density of the permanently formed deposit.

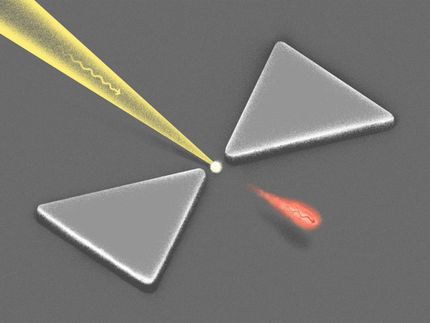

With the advent of nanotechnology, not only can we deposit tiny particles, but the target surfaces or substrates can be tailored to control the resulting structures.

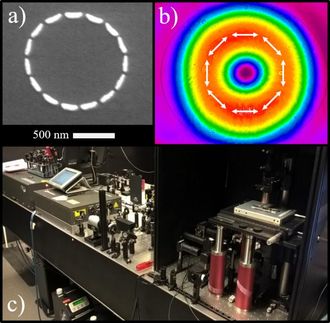

This article addresses the precision that must exist in the pattern of the target surface, in order to achieve high perfection and high coverage in the pattern of deposited particles. To do this, it compares RSA on three types of surfaces: a continuous (non-patterned) lattice, a precisely patterned surface, and a surface with small imprecisions in the pattern. The researchers find that very small imprecisions can make RSA proceed as if the surface is continuous. The consequence is that the deposition process is less efficient, and the ultimate coverage is much lower. In the process of RSA, a continuous surface is covered slowly with a larger fraction of the area remaining uncovered than a precisely lattice-patterned surface. In the past when surfaces on which microscopic particles were deposited were naturally flat (continuous) or had a lattice-structure, the importance of small imprecisions had not been recognized.

Vladimir Privman at Clarkson University has been involved in studying aspects of such systems since 2007; however this study, conducted with graduate student Han Yan, was the first to consider the imprecision in the surface lattice-site localization, rather than in the particle size uniformity.

Initially suggested by computer modeling, their results were later derived by analytical model considerations which are novel for the research field of RSA.

"The greatest difficulty was to understand and accept the initial numerical finding that suggested results that seemed counterintuitive," Privman explained. "Once accepted, we could actually confirm the initial findings, as well as generalize and systematize them by analytical arguments."

Pre-patterned substrates have been studied for applications ranging from electronics to optics, to sensors, and to directed crystal growth. The reported results suggest that efforts at precise fixed positioning and object-sizing in nano-manufacturing might be counterproductive if done as part of forming structures by RSA, under practically irreversible conditions. A certain degree of relaxation, to allow objects to "wiggle their way" into matching positions, may actually be more effective in improving both the density and rate of formation of the desired dense structures, Privman said.

This work has implications that the team is preparing to explore.

"Now that we have realized that not only particle non-uniformity, but also substrate-pattern imprecision have substantial effects on the dynamics of the RSA process, we will begin studying various systems and patterning geometries, expanding beyond our original model," Privman said.

Original publication

Vladimir Privman and Han Yan; "Random sequential adsorption on imprecise lattice"; J. Chem. Phys.; 2016

Original publication

Vladimir Privman and Han Yan; "Random sequential adsorption on imprecise lattice"; J. Chem. Phys.; 2016

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.