Yale researchers’ technology turns wasted heat into power

Researchers at Yale have developed a new technology that could make energy from the low-temperature wasted heat produced by industrial sources and power plants, tapping into a widely available — and mostly unused — resource.

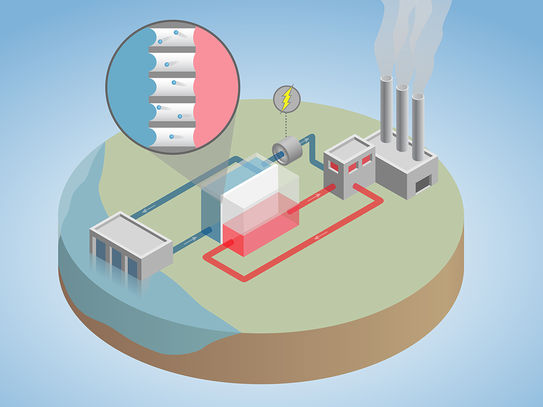

The temperature difference between a waste heat source and the environment drives water across the nanobubble membrane (enlarged) and through a turbine to generate electricity.

Yale University / Elimelech Research Group

It is estimated that recoverable waste heat in the U.S. alone could power tens of millions of homes. Although existing technologies can reuse high-temperature heat or convert it to electricity, it is difficult to efficiently extract energy from low-temperature heat waste due to the small temperature difference between the plant’s heat discharge and the surrounding environment. Additionally, conventional systems are designed to target a specific temperature difference, so they’re less effective when there are fluctuations in the output of waste heat.

Researchers at Yale’s Department of Chemical and Environmental Engineering have developed a new technology that overcomes these challenges. The key is a “nanobubble membrane” that traps tiny air bubbles within its pores when immersed in water. Heating one side of the membrane causes water to evaporate, travel across the air gap, and condense on the opposite side of the membrane. This temperature-driven flow of water across the membrane is then directed to a turbine to generate electricity.

To prove the concept, the team built a small-scale system and demonstrated that the nanobubble membranes could produce pressurized flows of water and generate power even with heat fluctuations and temperature differences as small as 20 degrees Celsius — making it feasible for use with the wasted heat from industrial sources. The findings were published in Nature Energy.

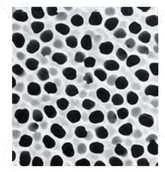

The researchers used nanostructured membranes with a surface chemistry that helps trap the air bubbles, keeping bubbles contained within pores even when large pressures are generated. These membranes, approximately as thick as two sheets of paper, were made from highly hydrophobic (water-repelling) polymer nanofibers.

“It was critical to identify robust air-trapping membranes that facilitate pressure generation,” said Menachem Elimelech, corresponding author on the paper and the Roberto C. Goizueta Professor of Chemical and Environmental Engineering at Yale. “Without the right membrane, water would displace the air in the pores, and the process would not be feasible.”

The demonstration of the prototype convinced the researchers of the value of the technology.

“We found that the efficiency of this system can exceed that of comparable technologies,” said Anthony Straub, first author on the study and a doctoral student in chemical and environmental engineering. “The process also only uses water, so it is cost-effective and environmentally friendly.”

The researchers plan to continue work on the technology, developing improved membranes that can better trap air bubbles. They also are investigating how large-scale future systems will perform.

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

Anopore™ by Cytiva

Precise filtration made easy with Anopore inorganic membranes

The aluminum oxide filter membrane that can increase the purity or yield of your analyte

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.