Standard to improve sustainable manufacturing

Advertisement

Anyone who's ever covered a wall with sticky notes to clearly map all of the steps in a process knows how valuable that exercise can be. It can streamline workflow, increase efficiency and improve the overall quality of the end result. Now, a public-private team led by the National Institute of standards and Technology (NIST) has created a new international standard that can "map" the critically important environmental aspects of manufacturing processes, leading to significant improvements in sustainability while keeping a product's life cycle low cost and efficient.

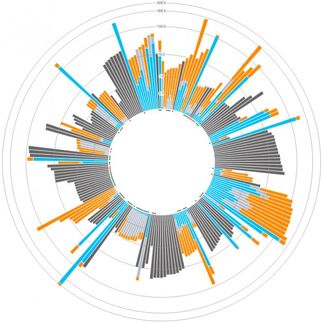

Graphic showing sustainability aspects for measuring and evaluating the performance of manufacturing processes. A new international standard created by a public-private team led by NIST guides manufacturers with a formal method for characterizing their processes to achieve environmental goals.

NIST

According to the U.S. Energy Information Administration, manufacturing accounts for one-fifth of the annual energy consumption in the United States--approximately 21 quintillion joules (20 quadrillion BTU) or equivalent to 3.6 billion barrels of crude oil. To reduce this staggering amount and improve sustainability, manufacturers need to accurately measure and evaluate consumption of energy and materials, as well as environmental impacts, at each step in the life cycles of their products.

However, making these assessments can be difficult, costly and time consuming, as many manufactured items are created in multiple and/or complex processes, and the environmental impacts of these processes can vary widely depending on how and where the manufacturing occurs. Additionally, the data collected are often unreliable, frequently not derived through scientific methods, and do not compare well with those from other types of manufacturing processes or from processes at different locations.

These issues are beginning to be addressed through a recently approved ASTM International standard for characterizing the environmental aspects of manufacturing processes (ASTM E3012-16). The guide provides manufacturers with a science-based, systematic approach to capture and describe information about the environmental aspects for any production process or group of processes, and then use that data to make informed decisions on improvements. The standard is easily individualized for a company's specific needs.

"It's similar to using personal finance software at home where you have to gather income and expenditure data, 'run the numbers' and then use the results to make smart process changes--savings, cutbacks, streamlining, etc.--that will optimize your monthly budget," said NIST systems engineer Kevin Lyons, who chaired the ASTM committee that developed the manufacturing sustainability standard.

"We designed ASTM E3012-16 to let manufacturers virtually characterize their production processes as computer models, and then, using a standardized method, 'plug and play' the environmental data for each process step to visualize impacts and identify areas for improving overall sustainability of the system," Lyons said.

For their next step, Lyons and his colleagues on the ASTM sustainability committee plan to define key performance indicators (KPIs)--metrics of success--for manufacturing sustainability that can be fed back into the E3012-16 standard to make it even more effective.

"In the long term, we'd also like to establish a repository of process models and case studies from different manufacturing sectors so that users of the standard can compare and contrast against their production methods," Lyons said.

Through a collaboration with Oregon State University, NIST held regional industry roundtables in Boston, Chicago and Seattle to learn how best to introduce the benefits of the sustainability standard to U.S. manufacturers, especially small- and medium-size firms. A report about those meetings will be published later this year.